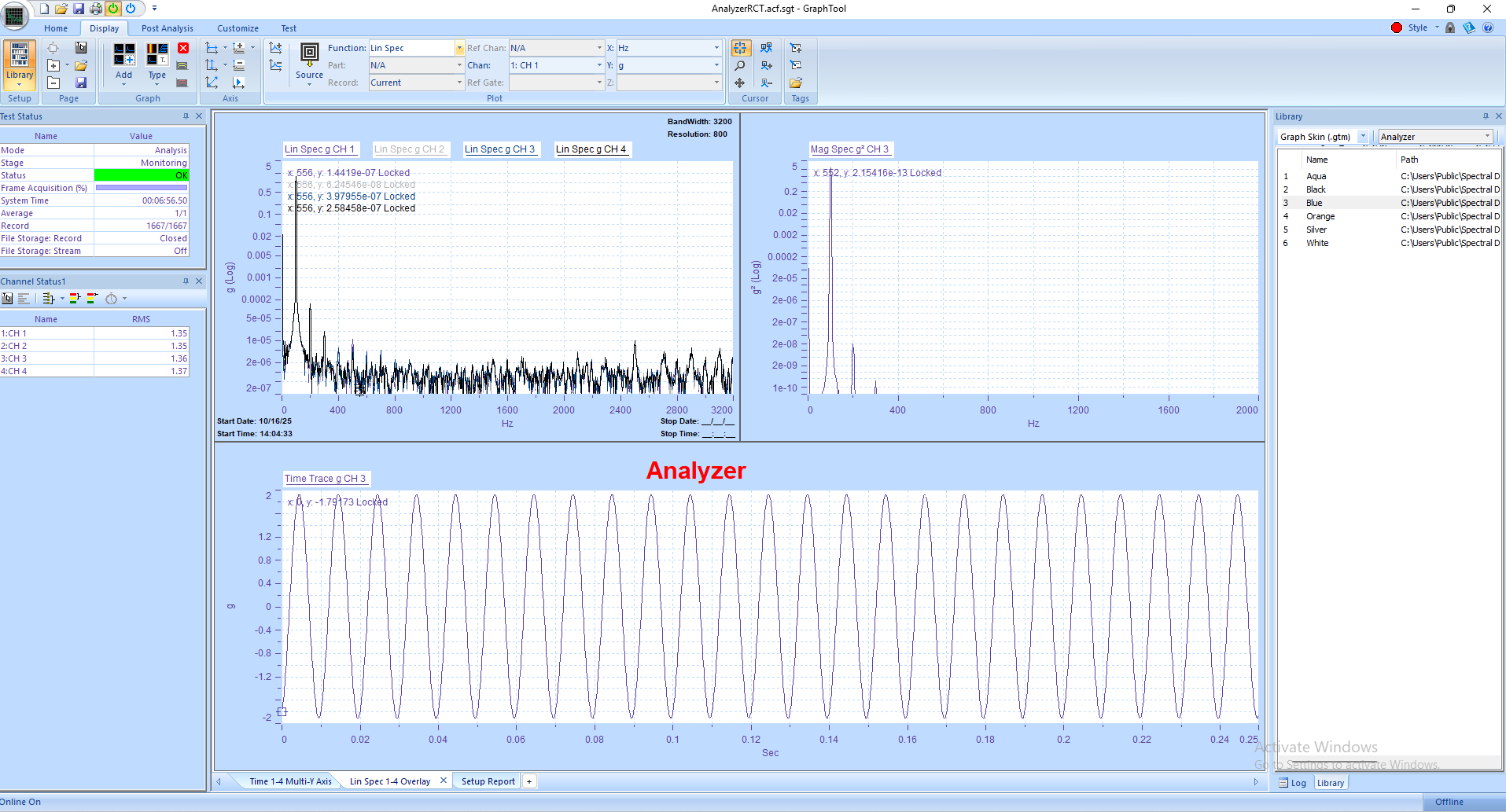

Analyzer

Panther Analyzer extends the power of Spectral Dynamics' next-generation Panther platform with...

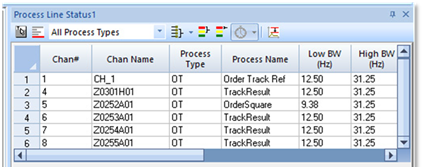

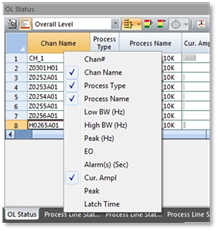

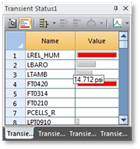

Process lines are essentially calculated values derived from your acquired data channels. They provide a way to monitor specific parameters or conditions during a test that aren't directly measured by a single sensor. Think of them as real-time calculated metrics that give you deeper insights into the behavior of your system under test.

Here are some examples of when process lines are really useful:

• Monitoring Overall Vibration Levels: You could set up a process line to calculate the Root Mean Square (RMS) value of an accelerometer's output. This gives you a single, continuous value representing the overall vibration level, which is often more practical to monitor than the raw, rapidly changing waveform.

• Monitoring Overall Vibration Levels: You could set up a process line to calculate the Root Mean Square (RMS) value of an accelerometer's output. This gives you a single, continuous value representing the overall vibration level, which is often more practical to monitor than the raw, rapidly changing waveform.

• Band-Pass Filtering: If you're interested in the energy within a specific frequency range, you can create a process line that calculates the energy within that band. For example, in a random vibration test, you might want to track the energy within a critical frequency band that could be particularly damaging to your test item.

• Calculating Peak Values: You could use a process line to track the maximum peak value (positive or negative) of a signal over a certain period. This is helpful for understanding the extreme excursions of a signal, even if the overall RMS value is within limits.

• Calculating Peak Values: You could use a process line to track the maximum peak value (positive or negative) of a signal over a certain period. This is helpful for understanding the extreme excursions of a signal, even if the overall RMS value is within limits.

• Monitoring Control Loop Performance: In some advanced setups, you might create process lines to monitor parameters related to the control loop's performance, such as the difference between the target and actual output, or the responsiveness of the system.

• Alarm and Warning Thresholds: Process lines are fundamental for setting up warning and alarm levels. You can define upper and lower boundaries for your calculated process line values, and the system can alert you or even stop the test if these thresholds are exceeded.

So, in short, process lines allow you to derive meaningful, actionable information from your raw test data, making it easier to monitor test progress, identify potential issues, and ensure the integrity of your test.

So, in short, process lines allow you to derive meaningful, actionable information from your raw test data, making it easier to monitor test progress, identify potential issues, and ensure the integrity of your test.