Swept Sine Test Advanced Tutorial

Complete Step-by-Step Guide for Swept Sine Vibration Testing

Spectral Dynamics Panther Control System

Modern Vibration Test Control System

SECTIONS 1-8: TEST SETUP & CONFIGURATION

Sections 1 through 8 cover the complete test setup process including:

- Introduction & Safety Overview

- Pre-Test Safety Inspection

- System Startup & Hardware Verification

- Channel Configuration

- Sweep Parameters Setup

- Control Setup

- Profile Creation

- Schedule Configuration (Optional)

Section 1: Introduction & Safety Overview

Welcome to the Panther Swept Sine Control application. This tutorial provides step-by-step guidance for configuring and executing swept sine vibration tests using the Panther vibration control system.

1.1 About Panther Sine Control

Panther Sine Control delivers unmatched precision and stability for swept-sine and stepped-sine vibration testing. Built on Spectral Dynamics' heritage as the inventor of closed-loop digital vibration control, Panther provides adaptive algorithms, real-time tracking filters, and built-in safety systems that ensure reliable, repeatable results across the full test spectrum.

1.2 Key Safety Principles

Before beginning any test setup, operators must understand and follow these critical safety principles:

- Panther continuously monitors over a dozen critical parameters up to 25 times per second

- Hardware watchdogs, automatic abort thresholds, and redundant safety logic ensure full system protection

- Safety limits must be configured appropriately for your test article and shaker system

- Never bypass safety features or exceed manufacturer-specified equipment limits

- Always perform a loop check to verify closed-loop system integrity before testing

CRITICAL: Safety isn't an afterthought in Panther—it's designed into the system. However, proper configuration and operator vigilance remain essential for safe test execution.

Section 2: Pre-Test Safety Inspection

Before initiating any vibration test, perform a thorough visual and functional inspection of the complete test system. This critical safety step prevents equipment damage and ensures accurate test results.

2.1 Physical Inspection Checklist

Test Article and Fixture:

- Verify test article is properly secured to the fixture

- Confirm fixture mounting to shaker head plate is secure and properly torqued

- Check for any loose components, fasteners, or potential hazards

- Ensure test article center of gravity is properly aligned with shaker axis

Transducer and Cabling:

- Inspect all accelerometer cables for damage, wear, or improper routing

- Verify transducers are properly mounted and oriented

- Confirm control transducer location is appropriate for test requirements

- Check for proper cable strain relief to prevent fatigue failures

Shaker and Power Amplifier:

- Verify shaker cooling systems are operational

- Check power amplifier for proper ventilation and no obstructions

- Inspect drive cable connections between controller and amplifier

- Confirm emergency stop controls are accessible and functional

2.2 Environmental Considerations

- Ensure adequate clearance around moving components

- Verify test area is clear of personnel during operation

- Check ambient temperature and humidity are within equipment specifications

- Confirm adequate ventilation for heat dissipation

Section 3: System Startup & Hardware Verification

This section covers the procedure for starting the Panther system and verifying proper hardware communication and functionality before configuring test parameters.

3.1 Launching Panther Sine Control

Step 1: Power on the Panther hardware unit and wait for initialization to complete (approximately 30-45 seconds).

Step 2: From the Panther main window, select the Sine application icon or navigate to File > New > Sine to create a new sine test.

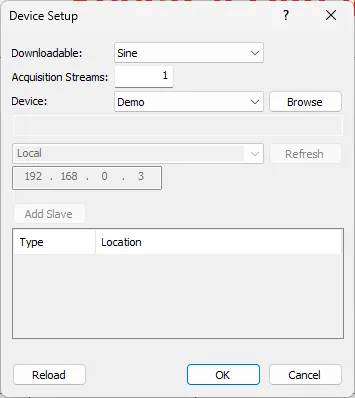

3.2 Input Type Configuration

The first configuration step establishes the connection between the software and Panther hardware.

Navigation: In the application's main window, click Setup > Set Input Type

Downloadable: Verify "Sine" is selected (this should be the only option available)

Acquisition Stream: Select the number of acquisition streams required (typically 1 for standard tests)

Device: Select hardware device (not a data file) for live testing

IP Address: Confirm the IP address matches your hardware location (default for Panther hardware: 10.0.0.2)

Note: If the system doesn't fully initialize, use the "Force Reload" option to restart the connection.

3.3 Hardware Verification

After establishing the software-hardware connection, verify proper system operation:

- Confirm green status indicators appear for the Panther unit in the GTX interface

- Verify the channel count matches your hardware configuration (8, 16, 24, or 32 channels)

- Check that the system reports "Ready" status with no error messages

- Review the log window for any hardware initialization warnings or errors

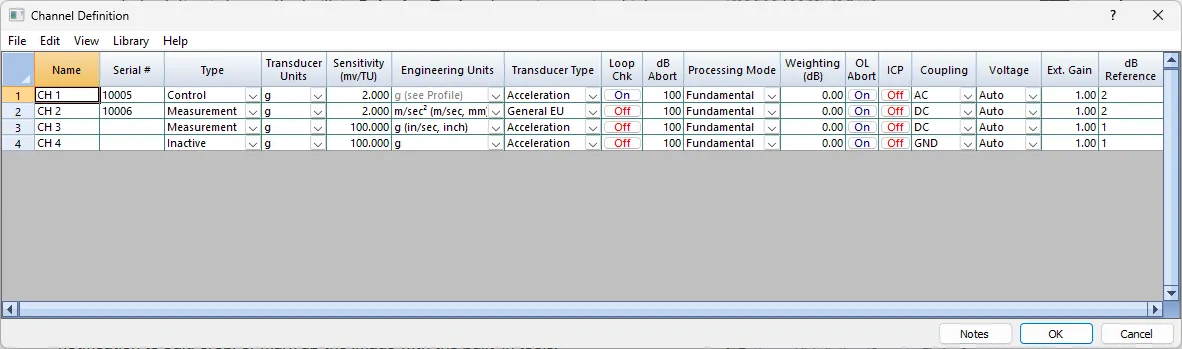

Section 4: Channel Configuration

Proper channel configuration is essential for accurate test control and data acquisition. This section details how to configure input channels, assign transducer sensitivities, and setup various channel function parameters.

4.1 Accessing Channel Setup

Navigation: Click Setup > Channels in the main application window

Note: Some settings are only displayed when in "Advanced" mode, which can be toggled using View > Advanced in the menu bar.

4.2 Channel Identification Parameters

Name: User-defined name for each channel (up to 20 characters). Use descriptive names like "Control-BaseX", "Limit-TopZ", or "Monitor-MidY".

Serial #: User-defined serial number for each channel (up to 10 characters) for tracking calibrated transducers.

4.3 Channel Type

The assignment type of each input channel:

- Inactive - No data acquired from this channel

- Control - Defines the control point on the test article. Must select at least one control channel. Loop check will be performed on all control related channels.

- Limiting - Monitors test article response against defined tolerance limits

- Measurement - Records data without affecting control or limits

- Abort - Monitors critical locations that will immediately abort the test if exceeded

4.4 Transducer Type

Select the signal type expected from the channel (See also Engineering Units Table options for adding/modifying units):

- Acceleration - Voltage proportional to single amplitude (0-pk) acceleration

- Velocity - Voltage proportional to single amplitude velocity

- Displacement - Voltage proportional to single amplitude displacement

- General EU - Engineering units defined in the Engineering Units table (available for Measurement and Limit channel types only)

Sensitivity: Enter the accelerometer sensitivity in units of mV/EU. Range: 0.01 to 1,000,000. This value is obtained from the transducer calibration certificate.

4.5 Loop Check Options

Loop check verifies closed-loop system integrity by confirming all control channels respond appropriately to the drive signal. Channels that do not normally respond should not have loop check enabled.

Loop Check Note: Control, Limit, and Abort channel types automatically enable loop check. This feature can be disabled if insufficient response is expected, but this should be done with caution.

4.6 dB Abort

The dB level entered in this entry is treated as an absolute Abort level independent from any control average or profile generated overall level Abort setting. This setting represents an absolute allowable upper error level limit on a per channel basis. This dB value represents the highest allowable error for this specific Limit/Abort channel measurement. An entry of 100.0 in this field will effectively disable the abort level option for the selected channel.

4.7 Processing Mode

Select how sine channel data is processed during the sine test:

- Fundamental (Recommended) - Uses digitally-based tracking filter centered at drive frequency for cleanest response

- BB RMS - Broadband RMS energy converted to equivalent peak amplitude

- BB Peak - Uses peak value (consider AC coupling options to remove DC offsets)

- BB Mean - Uses mean value (consider AC coupling options to remove channel DC offsets)

4.8 Weighting (dB)

Allows specifying a channel weighting factor (in dB) to provide a relative channel data bias when the data is combined to calculate an averaged level value for control purposes. (Not typically used in standard test configurations.

0 dB assumes uniform weighting).

4.9 OL Abort

This channel specific option will trigger a test abort if a voltage overload is detected on the channel. Note that an overload (depending on severity) can cause a truncation of the measured channel data value. Such truncations can be utilized (for example if using multiple control channels) and critical control calculations can be compromised due to using lower than actual measurement values. There are some cases where overloads can be tolerated and aborting the test may be considered too severe an option. Enabling this option will force a test abort upon detection of any channel data overload. For example, if using a Measurement channel, then an overload on that channel would not affect the control calculations so some overloads could be tolerated.

4.10 Signal Conditioning Settings

ICP: Enable ICP (IEPE) power for compatible transducers. Provides 4 mA constant current excitation. Must use AC coupling with ICP enabled.

4.11 Coupling

Select the input coupling mode:

- AC - High-pass filter with 3dB cutoff at 0.2 Hz blocks DC offset (Required for ICP power)

- DC - Necessary when DC offsets vary but average to zero

- AC-MN – Uses standard AC coupling and also removes dynamically calculated mean offset

- DC-MN – Uses standard DC coupling and also removes dynamically calculated mean offset

- GND - Signal input is grounded/Off

4.12 Voltage Range

The voltage range should be set to ±12 volts unless you have specific knowledge of the expected signal levels(for example on control channels). Auto-ranging is available but may introduce transient noise during range changes.

Recommended Setting: Set voltage range to ±12V and disable auto-ranging for most stable operation.

Step 4.13: Configure Voltage Range

Auto Range (Recommended):

- Select 'Auto' from voltage dropdown; Panther dynamically optimizes input range during acquisition.

- User Selectable fixed input full scale voltage range selections available otherwise for cases of high dynamic range

4.14 Ext Gain

This field allows specification of any external amplifier/signal conditioning that would affect the overall channel measurement value. This gain factor is a simple linear factor (non 0) that represents the amplification/attenuation of any external equipment.

4.15 dB Reference

This is the reference level (in engineering units) for the channel data. This is the reference that will be utilized when calculating any data derived parameter that will be represented as a decibel (dB) value. For example, when using dB as a Y axis display selection.

Equation: dB = 20.0 x Log10( Value/dB_Reference)

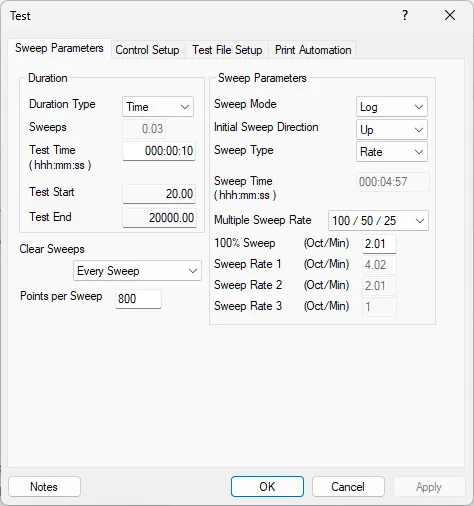

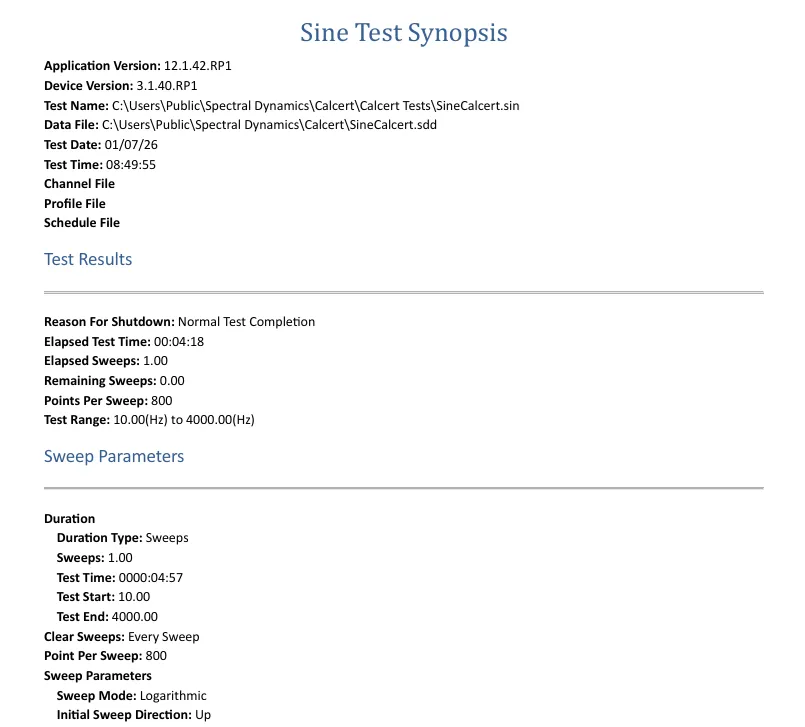

Section 5: Sweep Parameters Setup

The sweep parameters define the fundamental characteristics of your sine test, including frequency range, sweep rate, duration, and control methodology.

Navigation: Click Setup > Test, then select the Sweep Parameters tab.

Typical Sweep Parameter Examples

General Qualification Test:

Frequency: 20-2000 Hz, Logarithmic, 2 Oct/min, 10 sweeps

Resonance Search:

Frequency: 10-3000 Hz, Logarithmic, 4 Oct/min, 1 sweep up

5.1 Test Duration Configuration

- Duration Type - Select whether the test is based on sweep count or total time:

- Sweeps - Specify the number of complete frequency sweeps to perform

- Test Time - Specify total test duration in hours:minutes:seconds

5.2 Sweep Frequency Range Definition

Test Start: Initial frequency in Hz. Typically 5-20 Hz for most vibration tests.

Test End: Final frequency in Hz. Common ranges extend to 2000-5000 Hz depending on test requirements.

5.3 Sweep Display and Storage Definitions

Clear Sweeps: Choose whether sweep data displays are cleared every sweep or every other sweep.

Points per Sweep: Defines the resolution of the sweep in points. Allowable range is 450-2400 points per sweep. Higher values provide finer frequency resolution.

5.4 Sweep Configuration

Select the sweep progression (Mode) type:

- Logarithmic (Recommended, Typical) - Frequencies vary on logarithmic basis with time (Octaves/minute)

- Linear - Frequencies vary linearly with time (Hz/second)

Initial Sweep Direction: Select Up (minimum to maximum frequency) or Down (maximum to minimum frequency). Most specifications require Up sweep at startup.

Sweep Duration Type (Choose Rate or Timed):

- Rate - Define sweep using rate values (Oct/min for logarithmic or Hz/sec for linear)

- Timed - Specify total time to complete one sweep

Sweep Time: If Timed is selected, enter the amount of time to complete a sweep. The system automatically calculates the corresponding 100% sweep rate.

Multiple Sweep Rate Options

Select the sweep rate options which would be utilized if running in Manual and/or Schedule mode:

- 100/50/25% - Auto calculates full, half, and quarter sweep rate selections in Manual and/or Scheduled mode

- Arbitrary – Allows custom Sweep Rate selections for 1, 2, and 3 values (Rate 1 must be fastest)

100% Sweep Rate: Main sweep rate as used during the test unless variable sweep rates are specified in the Sine Schedule table. This value serves as the reference for 50% and 25% calculations (unless User specifies Arbitrary).

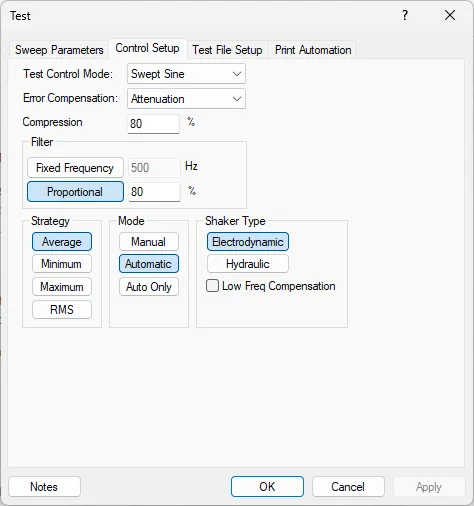

Section 6: Control Setup

The control setup defines how Panther maintains the specified test levels and compensates for system dynamics. Proper control configuration ensures accurate test execution and optimal control loop stability.

Navigation: Click Setup > Test, then select the Control Setup tab.

6.1 Test Control Mode

Test Control Mode: Select the primary test mode:

- Swept Sine - Standard continuous frequency sweep

- Search and Dwell - Automatic resonance detection with programmable dwell

- Step Sine - Discrete frequency-by-frequency step dined output and measurement

- Sine Analysis - Real-time amplitude, phase, and transfer function computation from time history data

6.2 Error Compensation Method

Error compensation determines how Panther corrects for system dynamics to maintain the desired control level. This is the basic methodology used for sine feedback control during the test.

Attenuation (Default/Recommended):

Standard method of control where the attenuator compensates for system dynamics point-by-point as the sine frequency changes. This adaptive approach provides excellent control through resonances and anti-resonances. Use this method for most applications.

6.3 Compression Rate

Compression (%): Defines the percentage compression (feedback) rate, typically 1-100%. Lower compression rates (<30%) provide smoother control and are recommended for low-frequency startups. Higher rates (>80%) allow faster response through resonances and anti-resonances but may introduce control instability. Typical setting: 50-80%.

Increasing compression speeds control response but may cause instability. Decreasing compression improves stability but slows response. Adjustment should only be made by experienced operators.

6.4 Filter (Bandwidth Types)

These are the definitions used for the processing filter bandwidth employed by the Sine control extraction.

There are 2 basic tracking filters available to apply to the acquired data stream:

Fixed: The bandwidth of the tracking filter is fixed to a specific frequency width independent of the current tracked frequency. The absolute bandwidth is specified in Hertz.

Proportional: The bandwidth of the tracking filter is proportional to the current tracked frequency value. As the tracked frequency increases, the bandwidth of the filter also increases (staying centered at the instant tracked frequency value). The bandwidth is specified as a per cent of the tracked frequency center point (typically 80%).

6.5 Control Channel Combining Strategy

Average: Channel data values will be numerically averaged to produce the current control value

Maximum: Channel data values will be compared and the Maximum used for the current control value

RMS: Channel data RMS values will be numerically averaged to produce the current control value

6.5 Control Operation Mode

This option is used to set the user control mode at test start to be Manual, Automatic or Automatic Only.

Manual: The test will start in a Manual mode allowing the user to change various settings and operations

Automatic: The test will start in an Automatic mode and use all defined test settings/schedule to run the test(s)

Auto Only: The test will start in an Automatic mode and not allow the user to deviate from the defined settings

6.5 Shaker Type

Allows the User to specify the type of shaker system being utilized. Allows the system to internally compensate for certain low frequency characteristics typically encountered with these shaker types.

Selections:

Electrodynamic: Relatively flat response once beyond the low frequency/stroke limitations

Hydraulic: Better low frequency response but typically suffers from high frequency limitations

Low Freq Compensation: Basically, the system can allow some additional compensation for low frequency content during operations

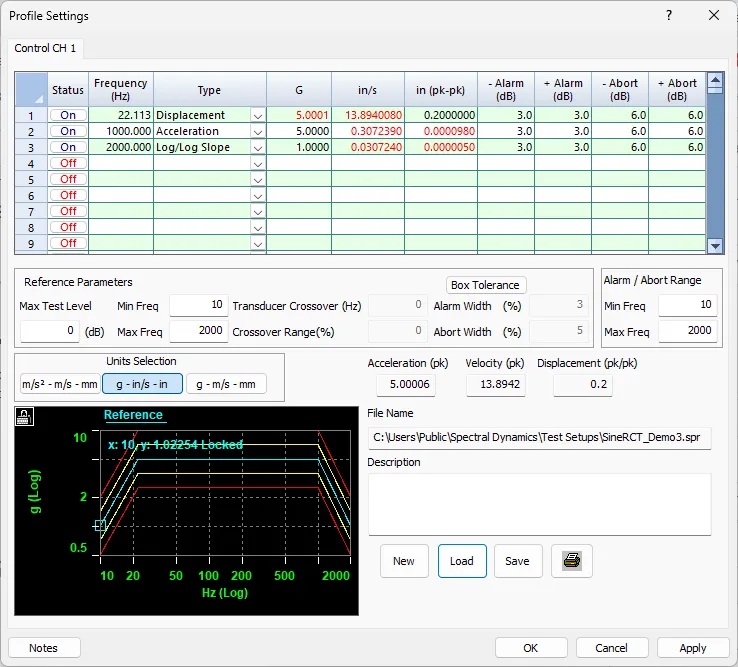

Section 7: Profile Creation

The test profile defines the desired vibration levels across the frequency range, including control levels, alarm limits, and abort thresholds. Panther uses this profile as the reference target during test execution.

Navigation: Click Setup > Profiles

7.1 Profile Configuration Basics

Units Selection: Choose the units for your profile: SI (g, m/s, m), Metric (g, cm/s, cm), or Imperial (g, in/s, in).

Reference Parameters:

Max Test Level: Allows running test above 0 dB level entered. Specifies maximum test level in dB above the entered Reference Profile. This enables test level margin above the profile.

7.2 Profile Spreadsheet Entry

The profile is defined using a spreadsheet interface where each row represents a frequency breakpoint:

Status: Toggle each profile line on or off.

Frequency (Hz): Specify the frequency for each breakpoint. Entries must be within the test frequency range.

Type: Select the segment type:

- Displacement - Peak-to-peak amplitude value

- Velocity - Zero-to-peak amplitude value

- Acceleration - Zero-to-peak amplitude value

- Logarithmic / Logarithmic Slope - Line on log-log basis (constant dB/octave)

- Linear / Linear Slope - Line on linear-linear basis

7.3 Alarm and Abort Tolerances

Alarm (dB): Alarm lines are the second most outer tolerance lines. When the control response exceeds alarm lines, the system logs the event. The value entered indicates how far in dB the alarm line is above/below the reference control line. Typical values: ±3 to ±6 dB.

Abort (dB): Abort lines are the outermost tolerance boundaries. When control response exceeds abort lines, the test immediately aborts. The value indicates how far in dB the abort line is above/below the reference control line. Typical values: ±6 to ±12 dB depending on test criticality.

7.4 Box Tolerance

Box Tolerance: Allows step changes in level between segments. Used when acceleration level changes exceed 0.5 dB. The Alarm and Abort Width (%) specifies these tolerances at transition points.

7.5 Profile Example

Typical Qualification Profile:

20 Hz: 0.5 g Acceleration

50 Hz: Logarithmic slope to 2.0 g

500 Hz: 2.0 g Acceleration (flat)

2000 Hz: Logarithmic slope to 0.8 g

Alarm/Abort: ±3 dB / ±6 dB throughout

7.6 Limiting and Abort Channel Profiles

If Limit or Abort channels are configured, additional profile tabs appear allowing separate tolerance definitions for each limiting channel. These profiles follow the same spreadsheet format as the control profile but define the acceptable response limits at these monitoring locations.

Limiting Channel Profiles: Define acceptable response boundaries for channels designated as Limit type. If response exceeds tolerance, an alarm is generated or test aborts depending on Alarm/Abort values.

Abort Channel Profiles: Define absolute maximum response levels for channels designated as Abort type. Any excursion beyond these boundaries causes immediate test termination for safety.

7.7 Saving Profile Files

File Name: The profile can be saved as a separate Sine Profile File (.spr) for reuse in other tests. However, the profile is also embedded in the main Sine Vib Test (.sin) file.

Description: User-defined description field for documentation purposes.

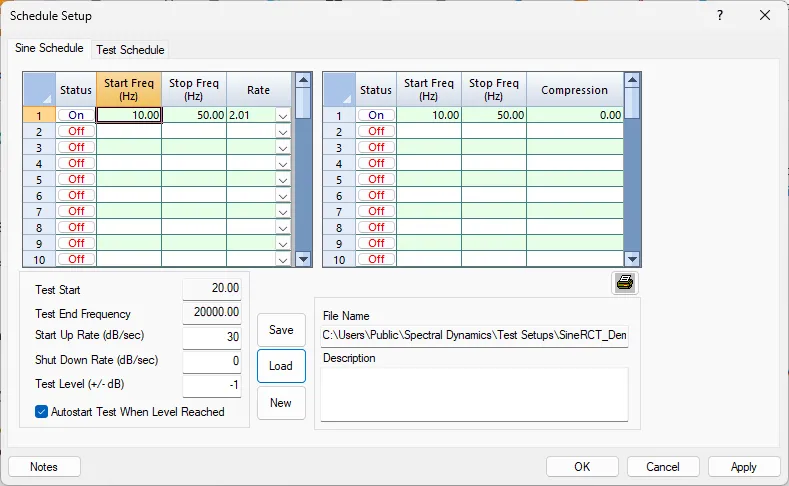

Section 8: Schedule Configuration (Optional)

Schedules provide advanced test automation capabilities, including variable sweep rates throughout the frequency range, multi-level testing, and automated test sequencing. While optional for basic swept sine tests, schedules enable sophisticated test protocols required by many specifications.

8.1 Accessing Schedule Setup

Navigation: Click Setup > Schedules

The Schedules dialog contains two tabs: Sine Schedule (for level and sweep rate control) and Test Schedule (for multi-test automation).

8.2 Sine Schedule (Variable Sweep Rates)

The Sine Schedule tab allows programming of variable sweep rates and compression rates throughout the frequency range. This enables slower sweeps through critical frequency bands and faster sweeps through benign regions.

Status: Toggle each schedule entry on/off.

Start Freq (Hz) / Stop Freq (Hz): Define the frequency band for this schedule entry. Must be within the Test Start/End Frequency range.

Rate (Hz/sec or Oct/min): Sweep rate for this frequency band. Common values: 0.5, 1.0, 2.0 Oct/min for logarithmic sweeps.

Compression (%): Compression rate for this frequency band (1-100%). Lower rates (<30%) provide smoother control for low-frequency startups. Higher rates (>80%) enable faster control through resonances and anti-resonances.

8.2.1 Schedule Entry Parameters

Test Start / Test End Frequency: Overall frequency range for the test. These values define the limits for all schedule entries.

Start Up Rate (dB/sec): Rate at which the test level increases from initial level to full test level. Typical values: 1-6 dB/sec.

Shut Down Rate (dB/sec): Rate at which excitation decreases when test completes or aborts. The achievable shutdown rate may be limited by control parameters such as frequency bandwidth and number of frequency lines.

Test Level (+/- dB): Test level offset in dB from the Reference Level Profile specified. Enter 0 to test at the profile level, or positive/negative values to test above/below profile.

Auto Start Test When Level Reached: When checked, the test automatically starts sweeping when the test level reaches within 10% of the specified starting amplitude. This eliminates the need for manual operator intervention.

8.2.2 Schedule Example

Multi-Rate Sweep Schedule:

20-50 Hz: 1.0 Oct/min, 30% compression (slow startup)

50-200 Hz: 2.0 Oct/min, 50% compression (standard rate)

200-500 Hz: 1.0 Oct/min, 80% compression (resonance region - slower with high compression)

500-2000 Hz: 4.0 Oct/min, 70% compression (fast sweep through benign region)

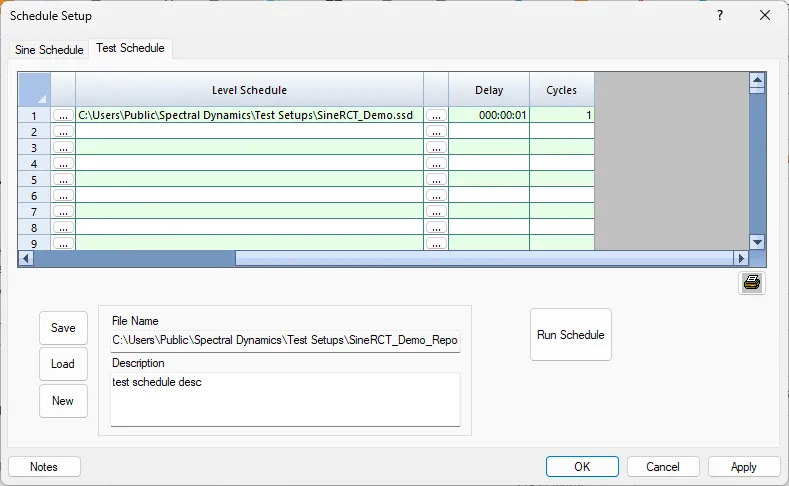

8.3 Test Schedule (Multi-Test Automation)

The Test Schedule tab enables automation of multiple different tests within a single application. This is useful for running different axes, profiles, or test conditions in sequence without operator intervention.

Profile Selection: Use the browse buttons […] to select different profiles for each test in the sequence.

Schedule Selection: Select different sine schedules for each test if variable sweep rates are required.

Delay (hrs:min:sec): Set the delay time between tests. This allows fixture changes, axis reorientation, or test article cool-down between test runs.

Number of Repetitions: Specify how many times the entire test sequence should be repeated.

Run Schedule: Press this button to start the automated test sequence.

8.3.1 Test Scheduling Status

Once the test sequence begins, the Test Scheduling Dialog displays the current test status:

- A box surrounds the current cycle entry to indicate the active test

- Completed tests appear with green checkmarks

- Text turns red during delay periods between tests

- The schedule continues automatically until all cycles and tests are complete

8.4 Saving Schedule Files

File Name:

Sine Schedule Files: .ssd extension

Test Sequence Files: .ssq extension

These files can be saved separately for reuse but are also embedded in the main Sine Vib Test (.sin) file.

Description: User-defined description for documentation purposes.

8.5 Advanced Test Automation

For automation across multiple applications (e.g., combining sine, random, and shock tests), use Mission Simulation Control accessible through the GTX environment. This allows creation of comprehensive test missions that span different test types and conditions.

Note: Mission Simulation Control is covered in separate documentation. Consult the GTX User Manual for complete mission programming guidance.

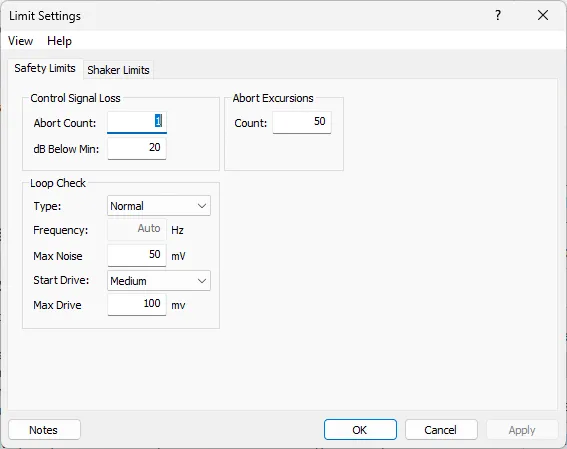

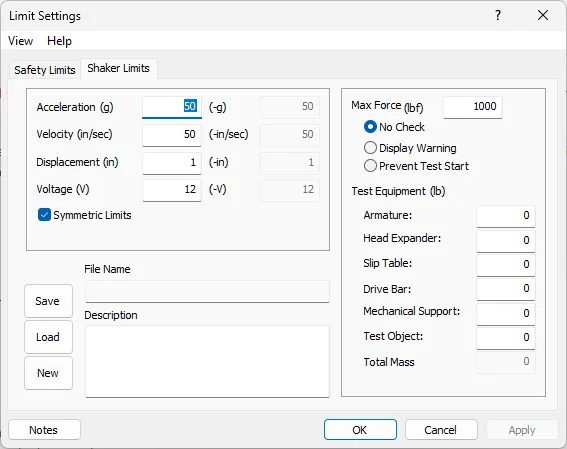

Section 9: Safety Limits Configuration

⚠ CRITICAL: Proper safety limit configuration is your primary defense against equipment damage and personnel injury. This section requires careful attention and must not be skipped.

Safety limits provide multiple independent layers of protection beyond profile alarm/abort lines. Panther monitors all safety parameters at 25 Hz (25 times per second) for industry-leading protection. This comprehensive section covers configuration of all safety systems in detail.

Navigate: Setup Menu → Limits

Understanding Panther Safety Philosophy

Defense in Depth Approach:

Panther employs multiple independent safety layers that work together to provide comprehensive protection:

- Layer 1 - Profile Limits: Frequency-dependent alarm/abort lines defined in your test profile

- Layer 2 - Control Signal Loss (CSL): Detects feedback problems like cable disconnection or sensor failure

- Layer 3 - Drive Limits: Prevents output overload by limiting maximum drive voltage

- Layer 4 - Force Limits: Protects shaker from mechanical overload based on mass and acceleration

- Layer 5 - Hardware Watchdog: Independent hardware protection that operates even if software fails

- Layer 6 - Emergency Stop: Manual override button for immediate test termination

Superior Capability: Panther's 25 Hz monitoring rate (every 40 milliseconds) is 25 times faster than typical competitive systems (1 Hz = every 1000 milliseconds). This means hazards are detected and responded to 25× faster, preventing damage that slower systems would miss entirely. At 40ms response time, Panther can stop a test before a single cycle completes at frequencies above 25 Hz.

Step 9.1: Configure Control Signal Loss (CSL) Detection

What is Control Signal Loss?

Control Signal Loss (CSL) detection is one of the most critical safety features in Panther. It continuously monitors the feedback signal from control channels to detect any condition where the system loses its ability to regulate the test. CSL detection protects against:

- Accelerometer cable disconnection or breakage during test

- Sensor failure or mounting failure (sensor falls off)

- Loss of IEPE power to sensor (power supply failure)

- Severe anti-resonances (notches) where response drops dramatically

- Control channel input failure or noise

- Fixture resonance causing signal loss

- DUT structural failure affecting sensor response

Why CSL is Critical:

Without feedback, the controller cannot regulate output. The system operates "open-loop" which means it has no way to know if the test level is correct. Loss of control signal can lead to:

- Rapid amplitude increase as controller tries to find response (over-testing)

- DUT damage or complete destruction within seconds

- Shaker overload and potential damage

- Invalid test results with no traceability

- Safety hazard to personnel and equipment

- Wasted test time and failed qualification attempts

The CSL protection system prevents these scenarios by immediately detecting signal loss and safely shutting down the test before damage occurs.

CSL Parameter 1: Abort Count

Definition: Abort Count is the number of consecutive monitoring cycles (at 25 Hz rate) that the control response must fall below the CSL threshold before a CSL abort is triggered. This prevents false aborts while maintaining quick response to real signal loss.

Understanding Abort Count:

- Each count represents one monitoring cycle = 40 milliseconds (1/25 second)

- Abort Count of 3 = 120 milliseconds (0.12 seconds) delay

- Abort Count of 5 = 200 milliseconds (0.20 seconds) delay

- Abort Count of 10 = 400 milliseconds (0.40 seconds) delay

- The count resets if signal returns above threshold

- Prevents false triggers when sweeping through deep anti-resonances (notches)

- Too low: False aborts at structural notches

- Too high: Delayed protection response to real cable failure

Recommended Abort Count Settings:

|

Application Type |

Abort Count |

Response Time |

|

Smooth response (no sharp resonances) |

3-5 |

120-200 ms |

|

Standard (typical structures) |

5 (Recommended) |

200 ms |

|

Sharp anti-resonances present |

7-10 |

280-400 ms |

|

Complex structures (many notches) |

10-15 |

400-600 ms |

Configuration Steps:

- Locate 'Abort Count' field in the Limits setup tab

- Start with the recommended value of 5 for initial tests

- Perform loop check and observe if false CSL aborts occur

- If false CSL aborts occur at notches, increase count by 2-5

- Maximum recommended: 20 counts (800 ms delay)

- For extremely deep notches (>30 dB drop), may need 15-20 counts

- Document final setting and rationale in test records

Note: Higher counts provide more immunity to false triggers but delay response to real signal loss

CSL Parameter 2: dB Below Minimum

Definition: The "dB Below Min" parameter defines how far (in decibels) the control channel response must drop below the expected minimum profile level before CSL detection is triggered. This works in conjunction with Abort Count to provide intelligent signal loss detection.

How dB Below Min Works:

- System continuously tracks the minimum expected response from your profile

- Alarm and abort limits are considered when establishing this minimum

- If actual response drops more than the specified dB below this minimum, CSL counter begins

- Must be set larger than your abort limit to be effective

- Accounts for normal system variations and measurement noise

- Automatically adjusts for different profile levels at different frequencies

Understanding dB Scale (Amplitude Ratios):

- -3 dB = 71% amplitude (29% reduction)

- -6 dB = 50% amplitude (50% reduction)

- -12 dB = 25% amplitude (75% reduction)

- -18 dB = 12.5% amplitude (87.5% reduction)

- -20 dB = 10% amplitude (90% reduction)

- -24 dB = 6.3% amplitude (94% reduction)

- -30 dB = 3.2% amplitude (97% reduction)

Recommended dB Below Min Settings:

|

Application Type |

dB Below Min |

Notes |

|

Flat response (no deep notches) |

12-15 dB |

Good protection, unlikely false triggers |

|

Standard (typical structures) |

15 dB (Recommended) |

Balanced protection vs. immunity |

|

Sharp anti-resonances present |

18-20 dB |

Increased immunity to notches |

|

Deep anti-resonances (>20 dB) |

25-30 dB |

May need adjustment after loop check |

|

Maximum protection needed |

10-12 dB |

Use with caution - may cause false aborts |

Configuration Procedure:

- Locate 'dB Below Min' field in Limits tab

- Start with 15 dB for first-time setups

- Perform loop check with this setting

- During loop check, carefully observe response through frequency range

- Note the deepest anti-resonance (notch) depth in dB

- If notches approach or exceed 15 dB, increase setting accordingly

- Add 5-10 dB margin above deepest observed notch

- Balance between protection (lower dB) and false trigger immunity (higher dB)

- Typical range: 12-25 dB for most applications

- Extreme cases may require 30 dB or more

- Document setting, deepest notch observed, and rationale

Step 9.2: Configure Loop Check Parameters

Purpose of Loop Check: Loop check is the single most important pre-test verification you can perform. This automated 10-30 second test confirms complete system integrity before committing to a full test run. Think of it as a "pre-flight check" for vibration testing.

Loop check verifies:

- Complete signal path from controller output through amplifier, shaker, test article, sensors, and back to controller input

- Adequate system response capability for the intended test level

- All cables and connections are intact and functioning

- Sensors are properly mounted and operational

- IEPE power is supplied and sensors are responding

- System dynamic characteristics (no excessive resonances)

- Drive voltage requirements are reasonable

- Phase relationships are correct

- Signal quality (coherence) is acceptable

⚠ CRITICAL: Loop check must be performed before EVERY test, even if nothing has changed. This 10-30 second investment prevents hours of wasted time and potential thousands of dollars in equipment damage.

Loop Check Type Selection

Panther offers three loop check modes, each with different thoroughness and duration:

1. Normal Loop Check (Recommended)

- Duration: 10-15 seconds typical

- Verification Level: Comprehensive system check

- Signal Type: Broadband random or single frequency sine

- Analysis: Response amplitude, coherence, drive voltage, phase relationships

- Best For: All production testing, qualification testing, standard operation

- Checks Performed: 15+ system parameters verified

- Pass/Fail Criteria: Automatic evaluation with clear indicators

2. Rigorous Loop Check

- Duration: 20-30 seconds

- Verification Level: Extended analysis with additional data collection

- Signal Type: Multi-frequency swept verification or extended broadband

- Analysis: All Normal checks PLUS frequency response analysis over full range

- Best For: Critical tests, first-time DUT testing, qualification milestones, complex setups

- Checks Performed: 25+ parameters including detailed frequency response

- Additional Benefits: Can identify resonances before full test

3. Fast Loop Check

- Duration: 3-5 seconds

- Verification Level: Quick connectivity check only

- Signal Type: Brief broadband excitation

- Analysis: Basic response presence, minimal detailed analysis

- Best For: Development testing, debugging, repeat tests on well-characterized stable setups

- Checks Performed: 5-8 basic parameters

⚠ WARNING: Fast loop check is NOT recommended for production, qualification, or any formal testing. Use only for development work.

Broadband Random vs. Single Frequency Loop Check

Loop Check Signal Type Selection: Panther offers two signal types for loop check, each with specific advantages:

Broadband Random (Recommended)

- Simultaneously excites entire frequency range (5 Hz to max)

- Provides quick overview of system frequency response

- Identifies resonances and anti-resonances immediately

- Better for detecting fixture or mounting issues

- More representative of actual test conditions for sine sweeps

- Superior for multi-resonance systems

- Recommended for all swept sine testing

- Duration: 8-12 seconds typical

Single Frequency Sine

- Uses one specific frequency for verification

- User selects frequency (typically mid-range, away from known resonances)

- Simpler signal, easier to interpret for troubleshooting

- Good for checking basic connectivity

- Useful when broadband causes control difficulties

- Best for step-sine testing verification

- Duration: 5-8 seconds typical

- Frequency selection critical - avoid resonances

Configuration Steps:

- Navigate to Setup → Limits → Loop Check tab

- Select Loop Check Type: Normal (recommended for most applications)

- Select Signal Type: Broadband Random (recommended) or Single Frequency

- If Single Frequency selected: Enter frequency value (e.g., 100 Hz for 10-2000 Hz range)

- Choose frequency at least 1 octave from known resonances

- Typical safe frequencies: 80-150 Hz for most structures

- Enable 'Auto Start Test When Level Reached' if desired

- Save configuration

Step 9.3: Configure Drive Voltage Limits (Shaker Safety Limits)

Understanding Drive Voltage: Drive voltage is the controller's output signal that feeds the power amplifier. This signal is then amplified (typically 50× to 200×) to drive the shaker. Proper drive limit configuration protects both the controller output stage and the amplifier input from overload.

Why Drive Limits Matter:

- Prevents controller output stage damage from excessive drive

- Protects amplifier input from overload

- Indicates when system cannot achieve test level (warning sign)

- Helps identify over-ambitious test specifications

- Prevents amplifier current limiting or clipping

- Ensures linear operation of amplifier

- Provides early warning of system limitations

Panther Drive Voltage Specifications:

- Maximum output capability: ±12 volts peak (24 volts peak-to-peak)

- Output impedance: 50 ohms

- Frequency response: DC to 100 kHz

- Distortion: <0.1% THD at rated output

- Noise floor: <10 µV RMS

- Slew rate: >50 V/µs

Determining Maximum Drive Voltage Setting:

The maximum drive voltage should be set based on your amplifier's input sensitivity and your typical test requirements. Use the following procedure:

- Check amplifier specification sheet for input sensitivity

- Common values: 1V, 2V, 5V, or 10V RMS for full output

- Convert RMS to peak: Peak = RMS × 1.414

- Example: 5V RMS input sensitivity = 7.07V peak

- Add 20-30% margin for control overhead

- Example: 7.07V × 1.25 = 8.84V peak (use 9V)

- Never exceed 12V (Panther maximum)

- Typical range for most systems: 6-10V peak

- For high-sensitivity amplifiers (1-2V input): Set 3-4V max drive

- For low-sensitivity amplifiers (5-10V input): Set 8-12V max drive

Max Drive Abort:

Panther can be configured to ABORT when max drive is exceeded:

- Test immediately stops if drive exceeds limit

- Prevents over-driving amplifier

- Ensures test validity

- Protects equipment

- Requires operator intervention to restart

- Best for unattended or qualification testing

Configuration Procedure:

- Navigate to Setup → Limits → Shaker Limits section

- Locate 'Voltage' field

- Enter calculated value based on amplifier sensitivity (typically 6-10V)

- Test setting with loop check to verify drive requirements

- Typical loop check should use <20% of max drive

If loop check uses >20% of max drive, test level may be too high

Step 9.4: Configure Shaker Force Limits

⚠ CRITICAL: Force limit configuration is MANDATORY for safe operation. Exceeding shaker force rating can cause catastrophic mechanical failure, injury, and equipment destruction.

Understanding Shaker Force: Electrodynamic shakers are rated by the maximum force (thrust) they can produce, typically specified in pounds-force (lbf) or Newtons (N). This force rating is the PRIMARY limiting factor for shaker operation and must NEVER be exceeded.

Force calculation: F = M × A

Where:

F = Force (pounds-force or Newtons)

M = Total moving mass (DUT + fixture + armature + associated hardware)

A = Peak acceleration (g or m/s²)

The shaker's force rating limits how much mass you can test at a given acceleration level.

Why Force Limits Are Critical:

- Exceeding rated force can destroy shaker bearings instantly

- Armature suspension can be permanently damaged

- Coil can separate from armature (catastrophic failure)

- Amplifier may be damaged by reflected energy

- DUT and fixture can be violently ejected

- Serious personnel safety hazard

- Typically requires factory repair ($10K-$50K+)

- Warranty will be voided if force limits exceeded

- Insurance may not cover damage from force overload

- Testing must stop immediately if force rating approached

Calculating Total Moving Mass: Accurate mass calculation is essential for force limit protection. You must include ALL masses that move with the shaker armature:

|

Component |

Source of Data |

Typical Range |

|

Shaker Armature |

Shaker specification sheet |

5-50 lbs depending on shaker size |

|

Head Expander (if used) |

Weigh on scale |

2-20 lbs depending on size |

|

Fixture/Adapter Plate |

Weigh on scale |

5-100 lbs depending on design |

|

DUT (Device Under Test) |

Weigh on scale |

Varies widely |

|

Mounting Hardware |

Weigh on scale |

0.5-5 lbs (bolts, brackets) |

|

Accelerometers |

Sensor spec sheet |

0.01-0.5 lbs per sensor |

|

Cables (moving portion) |

Estimate |

0.1-1 lb depending on length |

Mass Calculation Example:

For a 1000 lbf (4448 N) shaker with the following components:

Component Masses:

- Shaker armature (from specs): 25 lbs

- Head expander: 15 lbs

- Fixture: 35 lbs

- DUT: 20 lbs

- Mounting hardware: 3 lbs

- Accelerometers (4 × 0.1 lbs): 0.4 lbs

- Cables: 0.6 lbs

Total Moving Mass = 99 lbs

With this mass, maximum acceleration before reaching force limit:

A_max = F_max / M = 1000 lbf / 99 lbs = 10.1 g peak

Adding 20% safety factor:

Safe acceleration = 10.1 g × 0.80 = 8.1 g peak maximum

This means for this configuration, you should NOT run tests above 8 g peak acceleration. If your test spec requires 10 g, you must reduce mass or use a larger shaker.

Force Limit Safety Factors

Professional vibration testing practice requires applying safety factors to shaker force ratings:

Conservative (Qualification/Reliability): 70-75% of rated force - Ensures long shaker life

Standard (Production): 80% of rated force - Good balance of safety and capability

Maximum (Development only): 90% of rated force - Short-term use only, monitor carefully

Emergency (Troubleshooting): 100% of rated force - Very brief duration, expert supervision required

Max Force Check Options:

Panther provides three options for force limit enforcement:

No Check: Force limits disabled - NOT RECOMMENDED except for expert development work under close supervision

Display Warning: Yellow warning shown if force limit approached - test continues but operator alerted

Prevent Test Start (RECOMMENDED): Test cannot start if calculated force exceeds limit - provides absolute protection

RECOMMENDATION: Always use "Prevent Test Start" for production and qualification testing. This provides absolute protection against force overload.

Configuration Procedure:

- Navigate to Setup → Limits → Force Limits section

- Locate 'Maximum Force' field

- Enter shaker rated force (from specification sheet)

- Apply appropriate safety factor (multiply by 0.75-0.90)

- Example: 1000 lbf shaker × 0.80 = 800 lbf entry

- Locate 'Total Mass' field

- Enter calculated total moving mass (all components)

- Verify units match (lbs or kg)

- Select 'Max Force Check' option: Prevent Test Start (recommended)

- System will automatically calculate peak acceleration limit

- Review calculated limit - does it meet test requirements?

- If calculated limit too low, must reduce mass or increase test setup capability

- Document all mass measurements in test records

Test Equipment Mass Tracking

Panther provides a detailed mass tracking feature that helps document and manage your test configuration. This is especially valuable for formal testing where traceability is required.

Mass Tracking Fields:

Armature Mass: From shaker specs - enter once for each shaker

Head Expander Mass: Weigh and enter - if no expander, enter 0

Fixture Mass: Weigh fixture/adapter plate separately

DUT Mass: Weigh actual test article

Other Mass: Sum of hardware, sensors, cables, accessories

Total Mass: Automatically calculated by Panther

Best Practices for Mass Measurement:

- Weigh components on calibrated scale (accuracy ±0.5 lb minimum)

- Weigh fixture with all mounting hardware installed

- Include all cables that move with armature

- Count and weigh all accelerometers

- Include mass of accelerometer mounting studs/adhesive

- Document measurement method and scale used

- Take photos of complete test setup for records

- Update mass entries if configuration changes

- Verify total mass calculation before each test

- Keep mass log for each fixture and DUT combination

Force Limit Practical Examples

Example 1: Small Shaker, Light DUT

Shaker: 200 lbf rated force

Safety factor: 80%

Available force: 200 × 0.80 = 160 lbf

Total mass: 15 lbs (armature) + 5 lbs (fixture) + 3 lbs (DUT) = 23 lbs

Maximum acceleration: 160 lbf ÷ 23 lbs = 6.96 g peak

Test requirement: 5.0 g peak

✓ PASS - Can safely run this test (5.0 g < 6.96 g)

Example 2: Medium Shaker, Heavy DUT

Shaker: 1000 lbf rated force

Safety factor: 80%

Available force: 1000 × 0.80 = 800 lbf

Total mass: 25 lbs (armature) + 15 lbs (expander) + 45 lbs (fixture) + 85 lbs (DUT) + 5 lbs (hardware) = 175 lbs

Maximum acceleration: 800 lbf ÷ 175 lbs = 4.57 g peak

Test requirement: 6.0 g peak

✗ FAIL - Cannot safely run this test (6.0 g > 4.57 g)

Solutions:

- Reduce fixture mass (lighter materials, optimize design)

- Reduce DUT mass if possible (remove non-essential components)

- Use larger shaker (2000 lbf would allow 9.14 g with same mass)

- Reduce test level to 4.5 g (requires test spec revision)

Example 3: Large Shaker, Qualification Test

Shaker: 5000 lbf rated force

Safety factor: 75% (qualification test - conservative)

Available force: 5000 × 0.75 = 3750 lbf

Total mass: 50 lbs (armature) + 30 lbs (expander) + 120 lbs (fixture) + 200 lbs (satellite component) + 10 lbs (hardware) = 410 lbs

Maximum acceleration: 3750 lbf ÷ 410 lbs = 9.15 g peak

Test requirement: MIL-STD-810 Truck Transportation = 5.0 g peak

✓ PASS - Substantial margin (5.0 g < 9.15 g)

Could run up to 9 g if needed with this configuration

Force Limit Configuration Summary

Critical Steps Checklist:

☐ Obtain shaker rated force from specification sheet

☐ Determine appropriate safety factor (75-90%)

☐ Calculate available safe force

☐ Weigh all moving mass components on calibrated scale

☐ Sum all masses including hardware, sensors, cables

☐ Calculate maximum safe acceleration (F/M)

☐ Compare with test requirements

☐ Enter values in Panther Force Limits section

☐ Select "Prevent Test Start" enforcement

☐ Verify calculation matches hand calculation

☐ Document all measurements and calculations

☐ Take photos of test setup for records

☐ Review force limit warning during loop check

☐ Update mass if configuration changes

Common Force Limit Mistakes to Avoid:

✗ Forgetting to include fixture mass

✗ Not updating mass when DUT changes

✗ Using 100% of rated force (no safety factor)

✗ Estimating mass instead of weighing

✗ Ignoring head expander mass

✗ Not including mounting hardware mass

✗ Disabling force check to "get test to run"

✗ Using wrong units (lbs vs kg)

✗ Not verifying total mass calculation

✗ Failing to update mass in software

Section 10: Loop Check Execution Procedure

⚠ MANDATORY: Loop check must be performed before EVERY test without exception. This 10-30 second verification prevents equipment damage and ensures test validity.

Loop check is your final verification before committing to a full test. This section provides step-by-step procedures for executing loop check, interpreting results, and troubleshooting common issues.

Step 10.1: Pre-Loop Check Safety Verification

Complete Safety Checklist (MANDATORY):

Visual Inspection:

☐ Shaker armature moves freely with no binding or scraping

☐ Minimum 1 inch clearance in all directions

☐ No foreign objects in or around shaker

☐ All mounting hardware visibly tight

☐ No cracks or damage visible on fixture or DUT

Electrical Inspection:

☐ All accelerometer cables secured and clear of moving parts

☐ BNC connectors finger-tight (not loose)

☐ No visible cable damage or wear

☐ Proper ground connections verified

☐ All cables have appropriate strain relief

Sensor Verification:

☐ Accelerometers mounted in correct orientations

☐ Stud mount preferred (verify torque applied)

☐ If adhesive mount: cured per manufacturer specs

☐ If magnet mount: strong attachment verified

☐ IEPE power enabled for all active channels

☐ Wait 5 seconds after enabling IEPE for stabilization

Personnel Safety:

☐ All personnel clear of shaker (minimum 3 feet)

☐ Eye protection available if required by facility

☐ Emergency stop button location known and accessible

☐ No one leaning on table or fixture

☐ Clear path to emergency stop

System Readiness:

☐ Amplifier powered on and warmed up (2+ minutes)

☐ Amplifier status indicators green/ready

☐ Cooling system operating (fans running)

☐ No amplifier fault indications

☐ Panther software connected to hardware

☐ Test file loaded and all parameters configured

Step 10.2: Amplifier Enable Sequence

⚠ CRITICAL: Amplifier must ALWAYS be powered on BEFORE starting loop check or test, and powered off AFTER test completion.

Correct Power-On Sequence:

1. Verify amplifier AC power connected and circuit breaker ON

2. Verify cooling system operational (air or water)

3. Check that drive signal cable connected from Panther to amplifier input

4. Verify shaker connected to amplifier output

5. Turn amplifier power switch to ON position

6. Observe status indicators change (typically red → yellow → green)

7. Wait for full warm-up period (1-2 minutes minimum)

8. Verify green "ready" indicator illuminated

9. Check that cooling fans are running audibly

10. Listen for any unusual sounds (buzzing, rattling, arcing)

11. If water-cooled: verify water flow indicator shows flow

12. Check amplifier gain setting if adjustable (should match system design)

13. Verify amplifier remains stable (no fault lights)

Amplifier Status Indicators:

|

Indicator |

Meaning |

Action Required |

|

Green / Ready |

Amplifier operational and ready |

Proceed with loop check |

|

Yellow / Warming |

Amplifier warming up |

Wait until green before testing |

|

Red / Fault |

Fault condition detected |

DO NOT TEST - Investigate fault |

|

Red / Overtemp |

Thermal overload protection |

Allow cooling, check ventilation |

|

Flashing Red |

Serious fault (overcurrent, DC) |

Power off immediately, investigate |

Common Amplifier Issues:

- Amplifier does not power on: Check AC power, circuit breaker, fuse; verify cooling system running

- Stays in warm-up/yellow status: Wait longer (up to 5 minutes for large amps); check for faults

- Fault light illuminated: Check input/output connections; verify no short circuits; check protection settings

- Unusual noise or smell: Power off immediately; inspect for damage; check cooling; contact service

- Intermittent faults: Check input signal level; verify proper grounding; inspect all connections

Step 10.3: Loop Check in Panther Software

What Happens During Loop Check:

- Controller outputs low-level test signal (typically 0.05-0.2 g)

- Signal fed to amplifier and drives shaker

- Shaker begins vibrating gently - THIS IS NORMAL AND EXPECTED

- Motion should be smooth and consistent

- Software displays real-time response on screen

- All enabled channels show live data

- Duration typically 10-15 seconds for Normal mode

- System analyzes response quality, drive requirements

Operator Monitoring During Loop Check:

⚠ CRITICAL: Never look away from the shaker during loop check. Be prepared to hit emergency stop if anything unusual occurs.

Watch For:

Normal Motion: Smooth, sinusoidal or random vibration at low amplitude

Abnormal Sounds: Rattling, scraping, clicking, or knocking - STOP IMMEDIATELY if heard

Excessive Motion: If displacement seems too large, hit emergency stop

Cable Movement: Cables should not move with shaker - if they do, STOP and reroute

Loose Components: Watch for any parts vibrating loose - STOP if observed

Visual Interference: No clearance issues should occur - STOP if contact observed

Unusual Behavior: Trust your instincts - if something looks wrong, STOP

Step 10.4: Evaluate Loop Check Results

Understanding Loop Check Pass/Fail: Panther automatically evaluates loop check results against multiple criteria and provides clear pass/fail indication. Understanding what Panther checks helps you interpret results and troubleshoot issues.

Automatic Checks Performed:

- Response Noise level: All enabled channels are evaluated for ambient noise floor

- Response Presence: All enabled control channels showing signal above noise floor

- Response Amplitude: Response within expected range for applied drive level

- Drive Voltage: Required drive voltage reasonable (<20% of max drive recommended)

- Phase Relationship: Phase between channels reasonable and consistent

- CSL Compliance: No control signal loss detected during check

- Force Limits: Calculated force within safe limits

- Noise Floor: Acceptable signal-to-noise ratio on all channels

Successful Loop Check Indicators:

✓ Successful status displayed prominently in software

✓ All channels show reasonable response curves

✓ Drive voltage required is <50% of maximum (preferably <20%)

✓ No error messages or warnings

✓ Response amplitude matches expected value (within ±20%)

✓ No unexpected resonances at very low frequencies

✓ System feels stable and controlled

✓ Physical observation: smooth, controlled motion

✓ No unusual sounds or vibrations

If Loop Check Passes:

- Review response curves on all channels

- Note any resonances observed for reference

- Check drive voltage used - should be reasonable

- Verify force calculation shows margin available

- Screenshot results for test records (optional but recommended)

- Note any observations in test log

- Proceed to test execution or ABORT if just checking loop check process

Failed Loop Check Troubleshooting

⚠ DO NOT PROCEED TO TESTING IF LOOP CHECK FAILS. Resolve all issues before attempting test.

Common Loop Check Failure Modes and Solutions:

|

Problem |

Likely Cause |

Solution |

|

No response on control channel |

Cable disconnected, sensor failure, ICP power off |

Check connections, verify ICP enabled, test cable continuity |

|

Very low response (<10% expected) |

Wrong sensitivity entered, sensor loose, wrong orientation |

Verify sensitivity, check mounting, confirm sensor orientation |

|

Excessive drive voltage (>80%) |

Too much mass, test level too high, resonance at loop frequency |

Reduce mass, lower test level, change loop check frequency |

|

Poor coherence (<0.80) |

Loose mounting, electrical noise, bad cable, fixture resonance |

Tighten hardware, check grounds, replace cable, inspect fixture |

|

Erratic or noisy response |

Loose hardware, poor sensor mounting, cable moving, interference |

Tighten all fasteners, improve sensor mount, secure cables |

|

Force limit exceeded |

Too much mass for test level, incorrect mass entry |

Reduce mass or test level, verify mass calculation |

|

CSL abort during loop check |

Deep anti-resonance, incorrect CSL settings, actual signal loss |

Increase CSL dB threshold, check cables, verify sensor mounting |

|

One channel much higher than others |

Resonance at sensor location, sensor near node, wrong sensitivity |

Relocate sensor, verify mounting, check sensitivity value |

|

Unexpected low frequency resonance |

Fixture resonance, table resonance, improper mounting |

Stiffen fixture, verify shaker mounting, check table |

|

Amplifier fault during check |

Overcurrent, short circuit, amplifier protection |

Check output connections, verify shaker coil resistance, inspect wiring |

Systematic Troubleshooting Procedure:

- Identify specific failure mode from error message or observation

- Review troubleshooting table above for that failure type

- Perform easiest checks first (connections, settings)

- Check one thing at a time and retest

- Document what you check and results

- If multiple issues, resolve them in order of severity

- After each fix, re-run loop check before proceeding

- Do not attempt "workarounds" - fix root cause

- If unable to resolve, contact technical support

- Never disable safety features to make loop check pass

Step 10.5: Record Loop Check Results

Proper documentation of loop check results is essential for:

- Formal test reports and qualification documentation

- Troubleshooting recurring issues

- Tracking system performance over time

- Regulatory compliance (ISO, MIL-STD, etc.)

- Training and knowledge transfer

Recommended Data to Record:

- Pass/Fail Status: Overall loop check result

- Date and Time: When loop check performed

- Operator Name: Who performed the check

- Test Setup ID: Fixture, DUT, and configuration identification

- Drive Voltage: Peak voltage required during check

- Coherence Values: For each control channel

- Response Levels: Peak response on each channel

- Force Calculation: Calculated force and margin to limit

- Resonances Observed: Frequencies and amplitudes

- Issues Encountered: Any problems and resolutions

- Screenshots: Capture of response plots and data

- Configuration Changes: Any settings adjusted during troubleshooting

Creating Loop Check Documentation:

- Take screenshot of loop check results window/log showing pass status

- Screenshot response vs. frequency plot/table for all channels

- Note drive voltage displayed

- Record coherence values if doing detailed analysis

- Save screenshots with descriptive names (date_test_loopcheck.png)

- Add to test report or documentation package

- Keep in electronic test records folder

- Print for physical test log if required

Superior Capability: Panther's loop check provides comprehensive system verification in just 10-15 seconds. The automatic pass/fail evaluation analyzes over 15 parameters simultaneously - providing confidence that competitive systems requiring manual interpretation cannot match. Panther's integrated data acquisition records complete loop check history for full traceability.

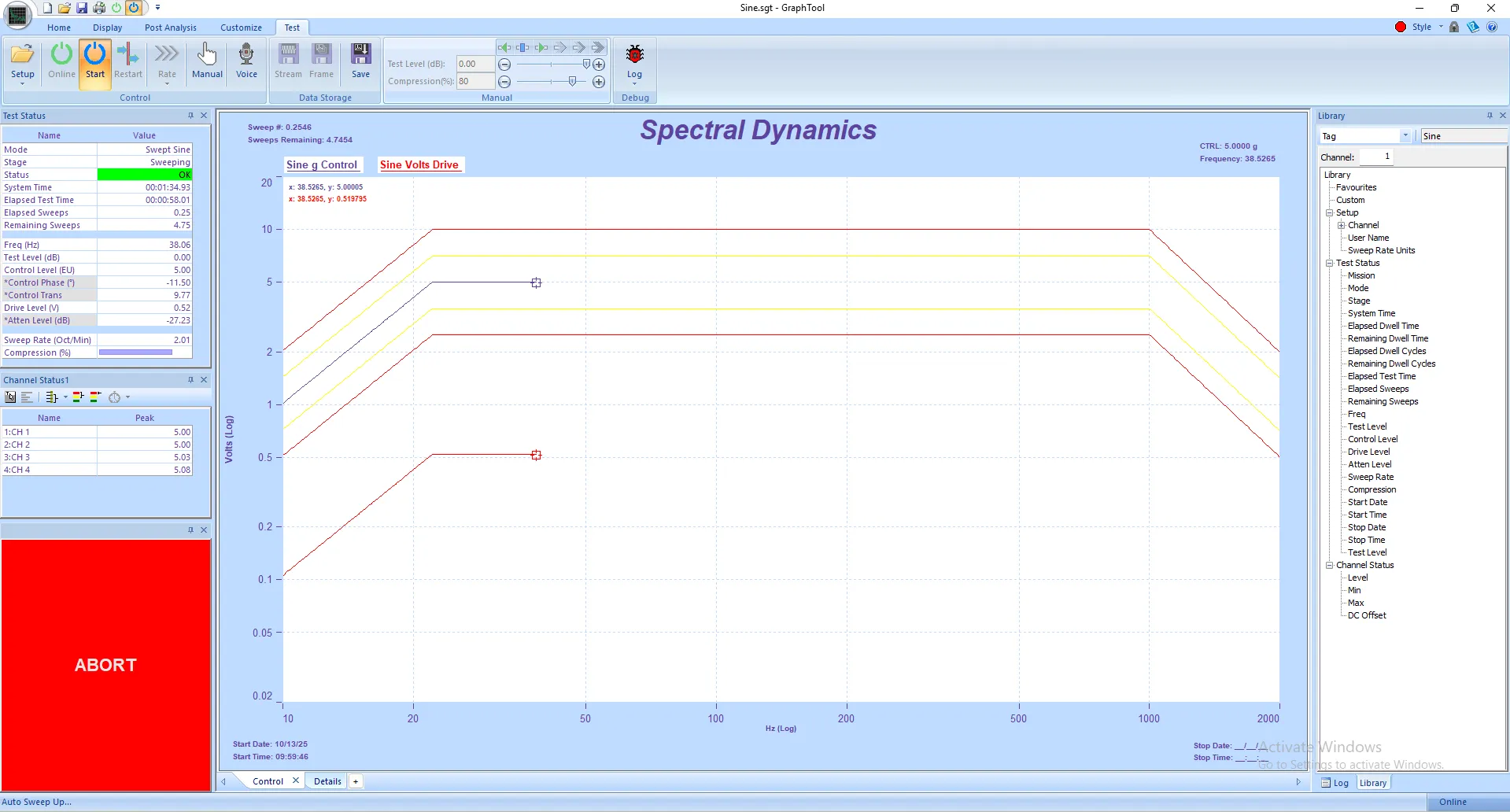

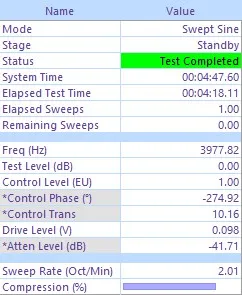

Section 11: Test Execution

⚠ CRITICAL: Never leave a running test unattended. Maintain constant visual contact with the shaker throughout the entire test duration.

With all parameters configured, safety limits set, and loop check successfully completed, you are ready to execute the swept sine test. This section provides comprehensive guidance for safe test execution, real-time monitoring, and proper response to any issues that arise during testing.

Step 11.1: Pre-Start Final Safety Verification

Final Safety Checklist (Complete Immediately Before Start):

Loop Check Status:

✓ Loop check completed successfully within last 15 minutes

✓ Pass status confirmed (green indicator)

✓ Drive voltage requirements reasonable (<50% max)

✓ No unresolved issues or warnings

✓ All parameters reviewed and correct

Physical Safety:

✓ All personnel minimum 3 feet clear of shaker

✓ Test area roped off or marked if public space

✓ Adequate clearance verified (minimum 1 inch all directions)

✓ No loose objects on or near shaker

✓ Cables secured and clear of moving parts

✓ Emergency stop button location confirmed

✓ Clear path to emergency stop maintained

Equipment Status:

✓ Amplifier powered on and showing green/ready

✓ Amplifier cooling system operating

✓ Panther software connected and responsive

✓ All accelerometer channels showing live data

✓ Test file loaded with correct parameters

✓ Profile displayed correctly

Test Parameters Verification:

✓ Frequency range correct (start and end frequencies)

✓ Sweep rate appropriate for application

✓ Test duration/number of sweeps correct

✓ Profile levels match test specification

✓ Alarm and abort limits properly set

✓ Safety limits configured (CSL, force, drive)

Documentation Readiness:

✓ Test log or data sheet prepared

✓ DUT identification recorded

✓ Test setup photographed (if required)

✓ Data storage location confirmed

✓ Operator name and date recorded

Step 11.2: Initiating the Test

Test Start Procedure:

- Ensure all items in Pre-Start checklist (11.1) are complete

- Position yourself where you can see both the computer screen and the shaker

- Verify hand position allows quick access to emergency stop

- In Panther GTX software, locate "START" button on test tab ribbon toolbar

- 6. Click the "START" button once

- Confirmation dialog may appear - read it carefully

- Click "Yes" or "Confirm" to proceed

- System immediately begins startup sequence

- DO NOT click anything else - let system proceed automatically

- Begin active monitoring (see Section 11.3)

Alternative Start Methods:

- Panther Test Control Dialog

- Remote start (if system configured for automation)

Understanding the Startup Sequence

When you press START, Panther executes a carefully orchestrated startup sequence designed to bring the system to test level safely and smoothly. Understanding this sequence helps you identify normal vs. abnormal behavior.

Phase 1: Initial Output (0-2 seconds)

- Panther outputs initial sine wave at starting frequency (e.g., 5 Hz)

- Amplitude is very low initially (typically 0.01-0.05 g)

- This is the "initialization" phase

- Shaker begins very gentle motion

- All channels should show initial response

- Drive voltage is minimal at this stage

- Control system engages tracking filters

Phase 2: Level Ramp-Up (5-30 seconds depending on startup rate)

- Amplitude increases at configured startup rate (e.g., 3 dB/second)

- 3 dB/sec = doubling every 3 seconds

- Smooth, gradual increase in motion

- All channels ramp proportionally

- Drive voltage increases steadily

- Control response should track reference line

- Motion becomes progressively more vigorous

- Operator should watch carefully during this phase

What to Watch During Ramp-Up:

- Smooth, proportional increase in motion (no sudden jumps)

- All channels ramping up together

- No unusual sounds (rattling, clicking, scraping)

- Fixture and DUT moving together (no relative motion)

- Cables not interfering with motion

- Drive voltage increasing gradually

- Control tracking reference line

- No alarm or warning indicators

Phase 3: Level Acquisition and Stabilization (5-10 seconds)

- System approaches target test level (0 dB reference)

- Typically stops ramp at 90-95% of target

- Final approach is slower for stability

- Adaptive control fine-tunes to exact level

- System evaluates response quality

- Control signal examined for acceptability

- May see slight overshoot and settling

- Status changes to "Test Level Reached" or "Ready to Sweep"

Phase 4: Dwell at Start Frequency (0-10 seconds, if configured)

- System may dwell briefly at starting frequency before sweeping (Auto mode)

- Allows thermal stabilization

- Confirms stable control before sweep begins

- Optional - depends on configuration

- If "Auto Start Test When Level Reached" enabled: skip this phase

Phase 5: Sweep Initiation

- If Auto Start enabled: Sweep begins automatically

- If manual start: Operator must click GTX "Sweep Up" button (Right green Arrow under Manual options)

- Frequency begins increasing (or decreasing if down sweep)

- Control continuously adjusts to maintain target level

- Test is now in active sweep mode

- Proceed to Section 11.3 for sweep monitoring

Step 11.3: Monitoring Active Sweep

Continuous Operator Vigilance Required:

⚠ Your attention during the sweep is critical. Most test failures and equipment damage occur during the sweep phase. Stay focused.

Visual Monitoring Priorities:

PRIORITY 1 - Physical Observation (60% of attention)

- Watch shaker and DUT continuously

- Observe motion amplitude and character

- Look for any unusual movement or vibration

- Check for loosening hardware

- Verify no cable interference

- Watch for clearance issues

- Listen for unusual sounds

PRIORITY 2 - Software Displays (30% of attention)

- Glance at control response vs. reference

- Check drive voltage level

- Monitor alarm/abort status (should be green)

- Observe frequency progress

- Check time remaining

PRIORITY 3 - System Status (10% of attention)

- Amplifier status lights (should remain green)

- Panther hardware status

- No error messages

Understanding Real-Time Displays

Panther provides multiple displays for monitoring. Understanding each helps you identify normal vs. abnormal operation.

Frequency vs. Amplitude Plot (Primary Display)

This is your main monitoring display:

Components:

Reference Profile Line: Your target - usually straight or with defined slopes

Control Response Line: Actual measured response - should closely follow reference

Alarm Limits: Yellow boundaries (typically ±3 dB from reference)

Abort Limits: Red boundaries (typically ±6 dB from reference)

Current Frequency Marker: Vertical line showing sweep position

Measurement Channel Lines: Additional channels for comparison

What to Look For:

- Control line tracking reference closely (within ±1-2 dB typical)

- Smooth progression with no sudden jumps

- Response passing through alarm zone briefly at resonances is normal

- Response should NOT touch or exceed abort lines

- Resonances appear as upward peaks

- Anti-resonances (notches) appear as downward dips

- Number and location of resonances may change between sweeps

2. Time History Display

Shows real-time waveform:

Normal Appearance:

- Clean sinusoidal wave

- Amplitude varies with profile level

- Frequency increases as sweep progresses (wave spacing changes)

- All channels in phase or with consistent phase relationships

Abnormal Indicators:

- Clipped or distorted waveform (amplifier limiting)

- Excessive noise or raggedness

- Sudden amplitude changes

- DC offset appearing

- Signal dropouts or interruptions

3. Control Panel/Status Display

Shows key parameters:

Current Frequency: Real-time frequency value (e.g., 127.5 Hz)

Current Level: Measured response amplitude (e.g., 4.8 g)

Reference Level: Target amplitude at this frequency

Drive Voltage: Current output voltage (e.g., 3.2V)

Sweep Direction: Up or Down

Sweep Count: Current sweep number (e.g., Sweep 1 of 2)

Time Elapsed: How long test has been running

Time Remaining: Estimated time to completion

Status: "Sweeping", "At Resonance", "Normal", etc.

Step 11.4: Monitoring Through Resonances

Resonances are Critical Monitoring Points:

⚠ Resonances are where most test failures occur. Pay extremely close attention when sweeping through resonant frequencies.

Recognizing Resonances:

- Sudden increase in response amplitude (peak on plot)

- Motion becomes more vigorous

- Drive voltage typically DECREASES (easier to excite)

- May hear change in sound/tone

- Fixture/DUT may shake more noticeably

- Control line may briefly enter alarm zone (acceptable if brief)

- Phase relationship changes rapidly

What to Watch at Resonances:

- Duration in Alarm Zone: Brief excursions OK; prolonged (>1-2 seconds) may indicate issue

- Approach to Abort Limit: Should never reach or exceed abort limit

- Control Stability: Should remain stable; if oscillating wildly, may need to abort

- Physical Response: Motion should be controlled; if violent or unstable, abort

- Drive Behavior: Drive should decrease at resonance; if increasing, problem exists

- Fixture Integrity: Watch for relative motion between parts

- DUT Condition: Look for any damage or changes

Panther Control Through Resonances:

Superior Capability: Panther's adaptive digital tracking filters with dedicated DSP maintain precise control through even severe resonances (Q>100). The system automatically adjusts compression and filter bandwidth in real-time to maintain stability. Competitive systems using FFT-based tracking often lose control or require manual intervention at high-Q resonances. Panther handles these automatically with no operator intervention required.

Common Resonance Behaviors

Understanding typical resonance patterns helps you distinguish normal from abnormal behavior:

1. Simple First-Mode Resonance (Most Common)

Characteristics:

- Single clean peak in response

- Occurs at lowest natural frequency of structure

- Symmetric rise and fall

- Drive drops significantly (may be 50% of anti-resonance level)

- Control maintains stable lock

- Q factor typically 10-50

Typical Frequencies:

- Small PCBs: 200-800 Hz

- Medium assemblies: 80-300 Hz

- Large structures: 20-150 Hz

Operator Action: Normal - continue monitoring, no action needed

2. High-Q Sharp Resonance

Characteristics:

- Very narrow frequency bandwidth (<1-2 Hz wide)

- Very high amplitude peak (may exceed alarm limits briefly)

- Extremely low drive voltage at peak

- Rapid amplitude change entering and exiting

- Q factor >100 possible

- May cause brief alarm condition

Typical Causes:

- Lightly damped structure

- Thin metal components

- Long cantilever beams

- Minimal structural damping

Operator Action:

- Watch closely but this is normal for lightly damped structures

- Brief alarm zone entry acceptable (<0.5 seconds)

- Panther should maintain control automatically

- If abort occurs, may need to widen abort limits or slow sweep rate

3. Multiple Coupled Resonances

Characteristics:

- Several peaks close together in frequency

- Complex response pattern

- Drive voltage varies rapidly

- May see beating or interference patterns

- Multiple modes interacting

Typical Causes:

- Complex assemblies with many components

- Coupled subsystems

- Multiple resonant paths

- Mode coupling

Operator Action: Normal - maintain observation, expect complexity

4. Fixture Resonance

Characteristics:

- Large amplitude increase

- Usually at lower frequencies (20-200 Hz)

- May affect multiple control channels similarly

- Fixture vibrates noticeably

- May amplify input significantly

Typical Causes:

- Fixture natural frequency excited

- Poor fixture design (insufficient stiffness)

- Inadequate fixture mounting

Operator Action:

- If fixture resonance is mild and control stable: Continue

- If causing control problems or excessive motion: Consider stopping

- Future: Redesign fixture to move resonance higher

Step 11.5: Handling Alarms and Aborts During Test

Alarm Conditions:

An ALARM indicates that a monitored parameter has exceeded its warning threshold but the test can continue. Alarms are logged but do not stop the test.

When Alarm Occurs:

- Alarm indicator changes color (typically yellow/orange)

- Audible alert may sound (if enabled)

- Status message indicates which channel/parameter caused alarm

- Event is logged with timestamp and details

- Test CONTINUES running

- Counter shows number of alarm excursions

Appropriate Response to Alarms:

- Note which channel caused alarm

- Observe if alarm is brief (passing through resonance) or sustained

- Brief alarms (<1 second) through resonances are normal and acceptable

- Sustained or repeated alarms warrant closer observation

- Check physical response - is motion excessive or unstable?

- If many alarms occurring: Consider reducing test level for future runs

- If alarm approaching abort limit: Prepare to manually stop if necessary

- Document alarm events in test log

Abort Conditions (Test Immediately Stops):

When ABORT occurs, test stops immediately and drive output is reduced to zero. This is a safety protection.

Common Abort Triggers:

|

Abort Type |

Cause |

Typical Action |

|

Profile Abort |

Response exceeded abort limit |

Widen limits or reduce test level |

|

CSL Abort |

Control signal loss detected |

Check cables and sensors |

|

Drive Limit Abort |

Max drive voltage exceeded |

Reduce test level or check system |

|

Force Limit Abort |

Calculated force exceeded limit |

Reduce mass or test level |

|

Hardware Fault |

Panther hardware issue detected |

Check hardware connections |

|

Amplifier Fault |

Amplifier protection triggered |

Check amplifier, verify connections |

|

Operator Abort |

Manual stop pressed |

Investigate reason for manual stop |

|

Software Exception |

Unexpected software condition |

Review logs, contact support |

Abort Response Procedure:

- System stops immediately - shaker motion decreases rapidly

- Abort dialog displays reason for abort

- Read and understand abort message carefully

- Note frequency at which abort occurred

- Note which channel or parameter caused abort

- Check physical setup - look for any changes or damage

- Take screenshot of abort message and plots

- Document abort details in test log

- DO NOT immediately restart - analyze cause first

- Determine root cause and corrective action

- If hardware issue: Inspect and repair before continuing

- If limit issue: Adjust limits or test level appropriately

- If configuration issue: Correct settings

- Only Restart (continue) or Start (new run) after understanding and resolving cause

Step 11.6: Emergency Stop Procedure

⚠ EMERGENCY STOP: Use emergency ABORT immediately if any unsafe condition occurs. Do not hesitate - equipment can be replaced, injuries cannot.

When to Use Emergency Abort:

- ANY unusual noise (rattling, scraping, banging, clicking)

- Excessive or violent motion

- Visible loosening of hardware

- Fixture or DUT showing signs of failure

- Cable interference with motion

- Clearance being compromised (hitting something)

- Smoke or burning smell

- Amplifier fault or distress

- Unstable or erratic control

- DUT damage occurring