Panther – Field Data Vibration Test Replication Software

Panther Field Data Replication Control delivers precision and performance in time-domain waveform...

Unattended Execution of Complex Multi-Stage Vibration Test Protocols

PANTHER's Mission Simulation feature enables complete automation of complex vibration test protocols that require multiple test applications to run sequentially without operator intervention. Unlike single-application test scheduling that automates tests within one application (such as running multiple random profiles in sequence), Mission Simulation orchestrates tests across different applications—allowing you to automatically run a sine sweep, followed by random vibration, followed by shock testing, all in a single unattended mission.

This vibration test automation capability is essential for qualification testing that requires multiple test types, overnight test execution, and any scenario where manual transitions between different test applications would create delays, introduce timing errors, or require constant operator presence. Mission Simulation transforms PANTHER into a fully autonomous test executive capable of running days-long test protocols without human intervention.

PANTHER's automated test sequencing provides comprehensive control over complex multi-application vibration test missions:

Mission Simulation operates at a higher level than individual application test scheduling. While test schedules within applications (like Random or Sine) allow you to chain together multiple profiles within that single application, Mission Simulation chains together complete tests from different applications into a unified sequence.

To create a mission, navigate to File → Mission from any PANTHER control application (Random, Sine, Shock, Random on Random, or Sine on Random). The Mission dialog allows you to build your test sequence by adding test files and configuring execution parameters for each.

For Each Test in the Mission, You Configure:

At the bottom of the Mission dialog, you also specify how many times to repeat the entire mission sequence. This allows you to run the complete multi-application test protocol through multiple cycles for durability testing or statistical validation.

Mission configurations are saved as .xts files (Mission File Application Automation) and can be loaded and modified for different test protocols.

The Start Mode setting for each test in your mission determines how that test transitions from the previous test. Choosing the correct start mode optimizes mission execution time while maintaining safety and data quality.

Auto Start issues a complete Start command, which performs all standard pre-test checks including ambient noise measurement, loop check, and (where applicable) System Identification. This is the safest mode and should be used when test conditions may have changed significantly since the previous test, or when transitioning between different test types that require verification of system configuration.

Auto Restart issues a Restart command if this test has already run at least once in the current mission loop. If this is the first run of this test, it issues a Start command instead. Restart mode speeds up test execution by using a pre-stored drive signal to ramp directly to full level, bypassing ambient noise checks and loop verification. This is most appropriate for repeated tests where conditions are stable and verification is unnecessary.

User mode pauses mission execution and prompts the operator (in the main application log or GTX) that the next test is ready for a Start command. The operator must manually issue the Start command for the test to begin. This mode is useful when manual verification or environmental condition confirmation is required before proceeding to the next test phase.

The Delay parameter (specified in seconds) controls how long the mission waits after one test completes before beginning the next test. This delay is critical for:

Delays can range from zero seconds (immediate transition) to hours if needed. When Start Mode is set to User, the delay parameter is ignored since the operator manually controls transition timing.

The Fail Action parameter determines mission behavior when a test aborts due to limit violations, control signal loss, or other system-detected problems. This setting does NOT apply to user-initiated aborts, which always end the current mission loop.

If Fail Action is set to Stop, any system abort immediately terminates the entire mission loop. This is appropriate when test integrity demands that all tests in the sequence complete successfully, or when a failure indicates a condition that would compromise subsequent tests (such as damaged test article or sensor failure).

If Fail Action is set to Continue, the mission proceeds to the next test even if the current test aborts. This mode is useful for screening tests where you want to collect maximum data even if individual test segments fail, or when testing to failure is part of the protocol and you want to continue characterizing behavior after a failure threshold is reached.

MIL-STD-810 and similar defense qualification standards often require sequential testing with multiple vibration profiles. A typical automated qualification test mission might include:

Without Mission Simulation, an operator must manually transition between each test type, leading to timing variations, potential sequence errors, and inability to run overnight. With Mission Simulation, the entire protocol runs automatically with perfect timing compliance.

Accelerated life testing often combines multiple stress types in specific sequences designed to accumulate equivalent field damage in shortened timeframes. A typical ALT mission might include:

Mission Simulation allows this complex protocol to run continuously through nights and weekends, dramatically accelerating time-to-market while ensuring consistent test execution.

Environmental Stress Screening for aerospace electronics typically requires cycling through multiple vibration profiles to precipitate infant mortality failures. A typical ESS mission includes:

Mission Simulation ensures consistent screening for every unit, with complete automation that allows 24/7 operation without operator fatigue or sequence errors.

Automotive components require durability validation across multiple operational scenarios. A typical automotive test mission might include:

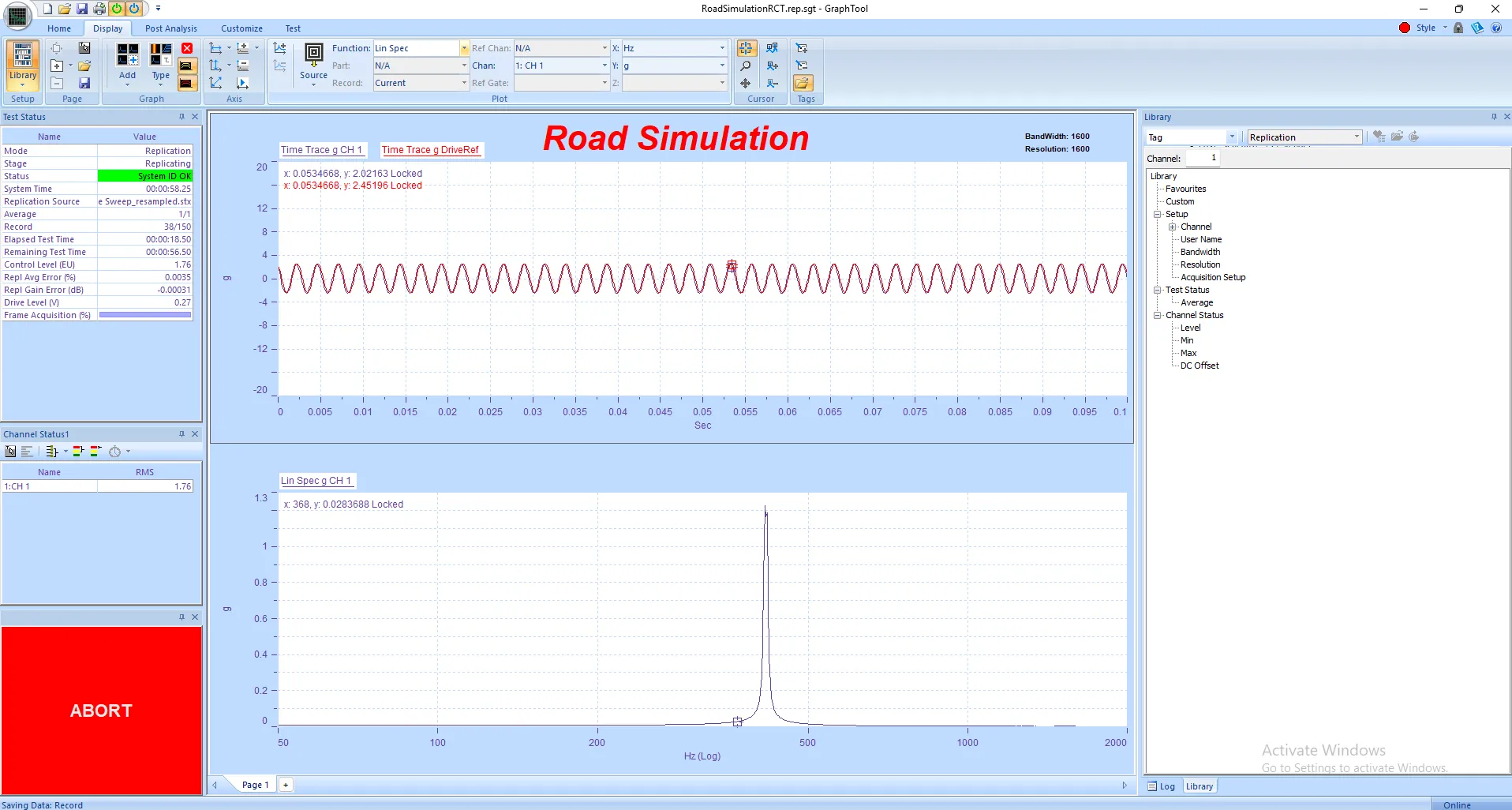

The ability to chain Road Simulation, Random, and Shock applications in a single mission allows realistic duty cycle testing that accurately represents field conditions.

Once a mission is configured, it is controlled through PANTHER's GTX (GraphToolX) application rather than through individual test application windows. This centralized control interface provides comprehensive mission management without needing to switch between different application windows.

In GTX, navigate to the Test tab to access mission controls. The Mission section provides the following functions:

Starts the currently defined mission setup. If clicked during an active mission run, it pauses the current test and provides a "Relaunch" option to resume from where it was paused.

If the mission has been paused, Reset returns the mission to its beginning state, allowing you to restart the entire sequence from the first test.

These buttons allow manual navigation through the mission test sequence. Next advances to the next test (if available), and Previous returns to the previous test in the mission. These controls are particularly useful when using User start mode or when manual intervention is required during mission execution.

To monitor mission progress in real-time, enable the Mission Status panel in GTX. Under the Home tab, in the View section, check the Mission checkbox. The Mission Status panel appears on the left side of GTX (you may need to resize the main graph window to view it).

The Mission Status panel displays:

This real-time status display allows engineers to monitor mission progress from anywhere on the network (if GTX is connected remotely), verify correct test sequencing, and identify exactly where in the mission sequence the system currently operates.

For maximum automation capability, Mission Simulation can be combined with PANTHER's Remote Control Interface (RCI) to create fully autonomous test laboratories. While Mission Simulation handles sequencing between different PANTHER test applications, RCI enables communication with external equipment like environmental chambers.

A complete automated test scenario might include:

This level of integration eliminates virtually all manual intervention, allowing complex combined-environment qualification testing to run continuously through nights, weekends, and holidays.

| Feature | Specification |

|---|---|

| Supported Applications | Random, Sine, Shock, Sine on Random, Random on Random, Road Simulation |

| Tests Per Mission | Unlimited (practical limit: system resources) |

| Iterations Per Test | 1 to 9999 |

| Mission Cycles | 1 to 9999 (repeat entire mission sequence) |

| Delay Range | 0 seconds to 999,999 seconds (277 hours) |

| Start Modes | Auto Start, Auto Restart, User-prompted |

| Failure Handling | Stop mission or Continue to next test |

| Mission File Format | .xts (Mission File Application Automation) |

| Control Interface | GTX (GraphTool X) with real-time mission status display |

| External Integration | RCI (Remote Control Interface) for environmental chambers and external equipment |

Mission Simulation enables true 24/7 unattended operation. Tests that would traditionally require an operator present to manually transition between different test types can now run continuously through nights, weekends, and holidays. This dramatically improves equipment utilization rates and accelerates time-to-market for product development and qualification.

Manual test sequencing is error-prone. Operators can load the wrong test file, miss protocol steps, or introduce timing variations that compromise test validity. Mission Simulation ensures perfect sequence adherence and timing consistency for every test run, every time—critical for regulatory compliance and data quality.

Many test standards specify exact sequences, timing, and rest periods between different test types. Mission Simulation enforces these requirements automatically, creating auditable test records that demonstrate standards compliance. The saved .xts mission files document exact test protocols and can be version-controlled for traceability.

By eliminating the need for operators to monitor test equipment and manually transition between test phases, Mission Simulation frees skilled engineers to focus on data analysis, test development, and other high-value activities rather than routine test execution and monitoring.

Mission Simulation ensures that every test article experiences identical test sequencing, timing, and conditions. This repeatability is essential for statistical analysis, production screening, and comparison testing where variations in test execution could mask or exaggerate product differences.

Automated test execution reduces labor costs associated with test monitoring and manual sequencing. Equipment that runs 24/7 completes more tests per year without capital expenditure for additional test systems. For high-volume screening and qualification testing, these efficiency gains create substantial cost savings.

PANTHER's Mission Simulation capability represents a fundamental advancement in vibration test automation. By enabling orchestration of multiple test applications into unified, unattended test sequences, Mission Simulation transforms vibration controllers from individual test tools into comprehensive test executives capable of executing complex multi-day protocols without human intervention.

Whether conducting MIL-STD-810 qualification sequences, accelerated life testing, environmental stress screening, or automotive durability validation, Mission Simulation ensures consistent execution, perfect timing compliance, and maximum equipment utilization. Combined with RCI for external equipment integration, Mission Simulation creates truly autonomous test laboratories that operate around the clock with minimal operator presence.

For test laboratories facing increasing test complexity, tighter schedules, and pressure to reduce costs while improving quality, Mission Simulation is not just a convenience—it's essential infrastructure for competitive test operations.