Spectral Dynamics invented closed-loop digital vibration control and continues to innovate with the Panther system — a unified vibration control and analysis platform designed for precision diagnostics in rotating machinery applications. Panther's RMA software provides engineers with the analytical tools necessary for accurate assessment of vibration, balance, and system health across a wide range of industrial and research environments.

The RMA application within Panther delivers high-resolution, real-time vibration data capture and playback for comprehensive machinery diagnostics. It allows users to examine transient run-up and coast-down conditions, steady-state operation, and dynamic speed variations of rotating equipment with complete signal fidelity. The system's gap-free acquisition architecture ensures continuous data integrity, while advanced post-processing tools provide instant replay and detailed analysis of speed, phase, and vibration amplitude relationships across the entire operating envelope.

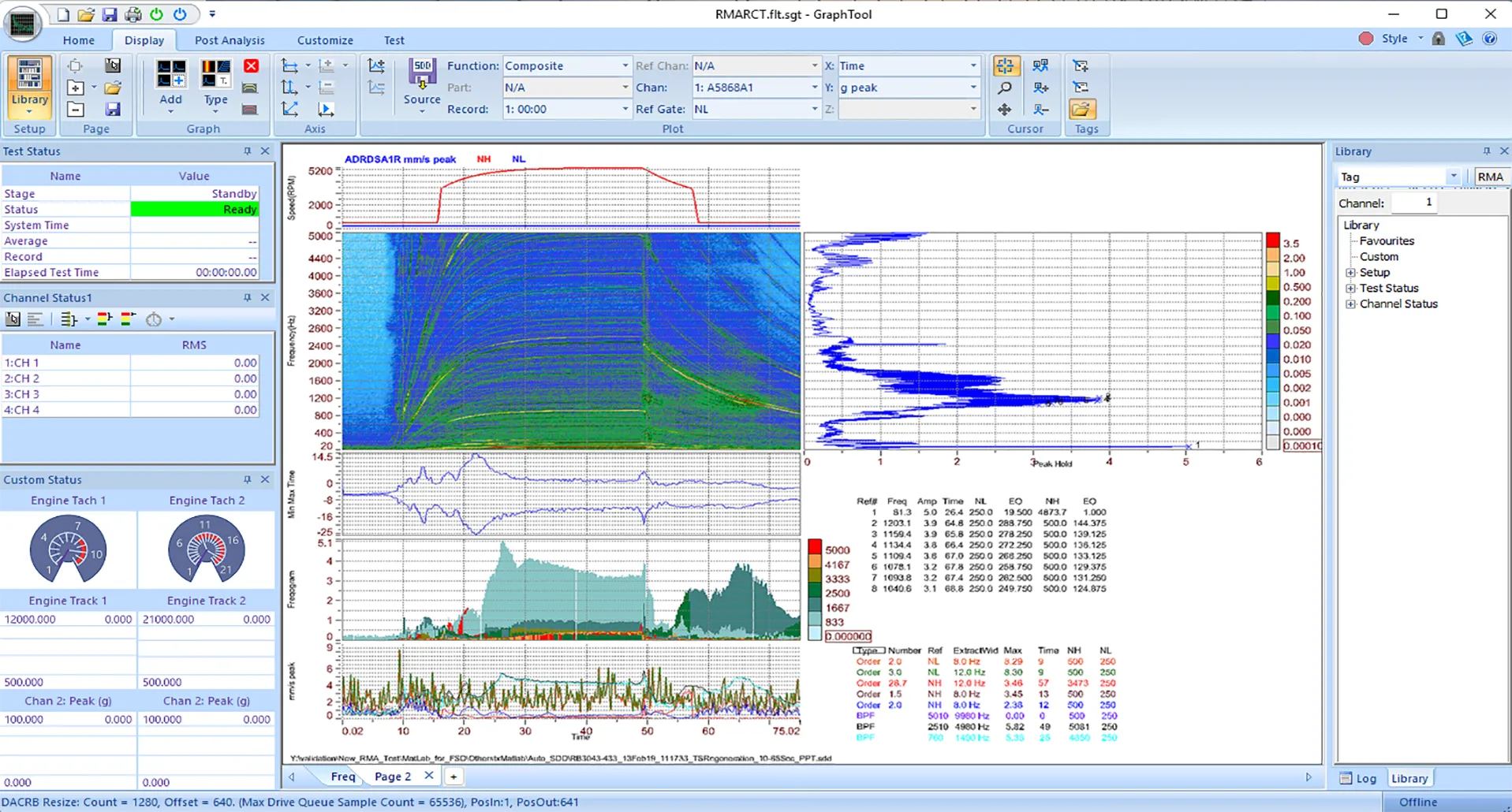

Panther RMA offers sophisticated visualization tools specifically designed for rotating machinery analysis. The Composite Plot and enhanced Composite II displays provide simultaneous visualization of frequency spectrum, time-domain waveforms, and rotational speed in coordinated three-dimensional representations. Campbell diagrams enable critical speed identification and resonance mapping, while waterfall plots reveal spectral evolution during transient operations. Order tracking plots automatically extract and display synchronous and sub-synchronous vibration components, and Bode plots show amplitude and phase relationships as functions of rotational speed for precise balancing and modal analysis.

A unique differentiator of Panther's RMA suite is the proprietary Composite Plot feature. This advanced visualization allows simultaneous display of correlated parameters such as vibration amplitude, rotational speed, and frequency response within a single three-dimensional representation. The Composite II enhancement adds dedicated speed gate plots and order/frequency tracking displays with configurable peak detection, historesis control, and minimum rise thresholds. Engineers can identify resonance zones, critical speeds, phase shifts, and order tracking behavior instantly — significantly reducing diagnostic time and improving test accuracy. The integrated peak hold table displays dominant frequency components with user-definable peak count and threshold filtering.

A unique differentiator of Panther's RMA suite is the proprietary Composite Plot feature. This advanced visualization allows simultaneous display of correlated parameters such as vibration amplitude, rotational speed, and frequency response within a single three-dimensional representation. The Composite II enhancement adds dedicated speed gate plots and order/frequency tracking displays with configurable peak detection, historesis control, and minimum rise thresholds. Engineers can identify resonance zones, critical speeds, phase shifts, and order tracking behavior instantly — significantly reducing diagnostic time and improving test accuracy. The integrated peak hold table displays dominant frequency components with user-definable peak count and threshold filtering.

The RMA application supports comprehensive data management through the GTX framework. Acquired data is stored in Spectral Dynamics Data (SDD) files with automatic frame indexing and metadata tagging. The Library feature enables organized storage and instant retrieval of test configurations, historical runs, and analysis templates. Data masking capabilities allow engineers to exclude specific time or speed ranges from analysis, and data can be exported to Excel for additional post-processing or reporting. The replay function provides frame-by-frame review with adjustable playback rates and synchronized cursor tracking across all display types.

All RMA functionality is integrated within the GTX software environment, providing a unified interface for test setup, execution, analysis, and documentation. The Library feature provides direct access to stored data files and previous runs, enabling rapid comparisons between live and historical data. Custom status panels display real-time RMS values, minimum and maximum amplitudes, phase information, and user-defined transient data streams. The interface supports full touch-screen operation on Windows PCs and Microsoft Surface devices, ensuring flexible control and review workflows. Automated report generation creates comprehensive test documentation with embedded graphics, data tables, and analysis results.

All RMA functionality is integrated within the GTX software environment, providing a unified interface for test setup, execution, analysis, and documentation. The Library feature provides direct access to stored data files and previous runs, enabling rapid comparisons between live and historical data. Custom status panels display real-time RMS values, minimum and maximum amplitudes, phase information, and user-defined transient data streams. The interface supports full touch-screen operation on Windows PCs and Microsoft Surface devices, ensuring flexible control and review workflows. Automated report generation creates comprehensive test documentation with embedded graphics, data tables, and analysis results.

|

Input Subsystem |

Output Subsystem |

|

Input Channels: 8 Channels Expandable up to 32 |

DAC: 20 Bit |

|

Dynamic Range: >110dB |

Max Output Amplitude: ±12 Volts Peak |

|

ADC: 24 Bit |

Max Output Current: 16 mA |

|

Amplitude Accuracy: ±0.20% of value or ±0.03% of full scale |

Amplitude Linearity: ±0.20% of value or ±0.03% of full scale |

|

Voltage Ranges: ±12V to ±0.5V in 8 steps (Auto Ranging) |

Max Output Rate: 262,144 Samples per Second |

|

Overload Detection: Full scale on all channels, analog and digital detection |

Image Attenuation: <96dB |

|

Voltage Coupling: AC or DC or GND |

Frequency Accuracy: ±5 ppm |

|

IEPE Power: 4 mA (24V max into open circuit) |

Freq Range Reduction: 10 stage smoothing filters |

|

Max Rated Input Signal: ±35 Volts Peak |

Reconstruction Filters: Analog 1kHz–25kHz, >96dB attenuation, ±0.15dB ripple |

|

Max Sampling Rate: 262,144 Samples per Second |

Output Impedance: 60 Ohms |

|

Input Impedance: 1 MΩ |

Output Type: Pseudo-Differential, 10Ω to Ground |

|

Connection Type: Pseudo-Differential |

Output Cable: Drives up to 50 feet of shielded 50Ω coax |

|

Calibration: Automatic Internal Digital Calibration (NIST referenced) |

Calibration: Internal Digital Calibration (NIST referenced) |

|

TEDS Compliant: Yes |

Calibration Constants: Digital Calibration Constants stored in ASCII file |

|

Tachometer Input: 1 MHz hardware input for precise phase synchronization |

COLA Output Level: 1 Volt Peak (post-filter) |

|

Host to Unit Communication: USB / Ethernet / Optional Wi-Fi |

Phase Synchronization: Better than ±1° across all channels |