Multiple Sample Rate Data Acquisition: Industry-Leading Flexibility

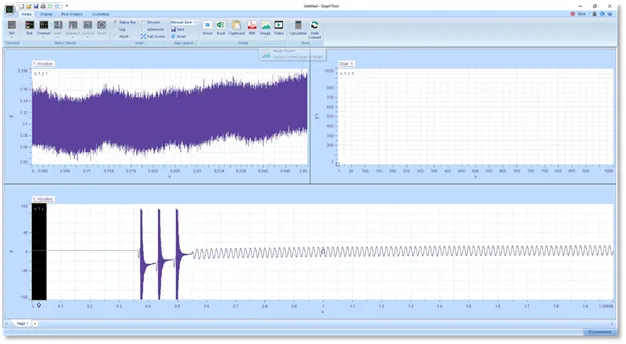

PANTHER's multiple acquisition streams capability represents a fundamental architectural advantage in vibration testing systems. While competing vibration controllers force all channels to share a single sample rate—creating compromises between high-frequency accuracy and storage efficiency—PANTHER uniquely allows engineers to define up to three independent data acquisition streams, each with its own user-selectable sample rate.

This exclusive capability enables simultaneous acquisition of vibration data at different rates tailored to your specific sensors and measurement requirements. For example, a typical multi-stream configuration might include:

- High-speed transient data (e.g., 262,144 samples/second) for shock testing, impact analysis, and SRS (Shock Response Spectrum) measurements

- Medium-speed control data (e.g., 25,600 samples/second) for precise random vibration testing and sine vibration control

- Low-speed environmental monitoring (e.g., 100 samples/second) for temperature sensors, strain gauges, and DC measurements

Each stream's sample rate is completely configurable—you select from any of the available sample rates your PANTHER vibration controller supports, choosing rates appropriate for each channel type. The examples above illustrate typical configurations, but you have complete flexibility to optimize each stream for your specific vibration test requirements.

All streams record simultaneously with perfect time synchronization, maintaining phase relationships across all channels while minimizing storage requirements and optimizing data quality for vibration analysis.

Key Benefits of Multi-Stream Vibration Data Acquisition

- Optimize sample rates independently for shock, vibration, and environmental sensors

- Reduce data storage requirements by 50-70% compared to single-rate systems

- Eliminate the need for multiple separate data acquisition systems

- Maintain perfect time correlation across all measurement streams

Multi-Stream Architecture: How Independent Sample Rates Work in Vibration Testing

PANTHER implements multiple acquisition streams through sophisticated digital signal processing architecture that maintains independent sampling, filtering, and decimation chains for each vibration measurement stream.

Configurable Sample Rate Flexibility for Each Data Stream

Primary Stream: The default acquisition path used for vibration control and primary measurements. Sample rate is determined by your application bandwidth setting (e.g., 25.6 kHz for random vibration control testing).

Secondary Stream 1 (Optional): Independent user-selectable sample rate for auxiliary vibration measurements. Can be configured for higher rates (transient capture, shock testing) or lower rates (environmental monitoring) without affecting primary control loop performance. Choose any available sample rate from your system that meets your measurement needs.

Secondary Stream 2 (Optional): Additional independent stream with its own user-selectable sample rate for specialized measurements such as tachometer signals, strain gauge data, or supplementary accelerometer channels requiring different bandwidth characteristics. Again, you select the optimal rate from your system's available options.

Independent Anti-Aliasing Filtering and Digital Signal Processing

Each data acquisition stream maintains its own:

- Anti-aliasing filter selection (1 kHz, 10 kHz, 25 kHz, or OFF) matched to sample rate

- Digital decimation ratio optimized for the target sample rate and frequency resolution

- Frame size and overlap settings for spectral processing and FFT analysis

- Trigger conditions and recording parameters for event-based data capture

This architecture ensures that high-speed shock capture on one stream does not force unnecessary high sample rates on channels monitoring slowly-varying parameters like temperature or DC voltage.

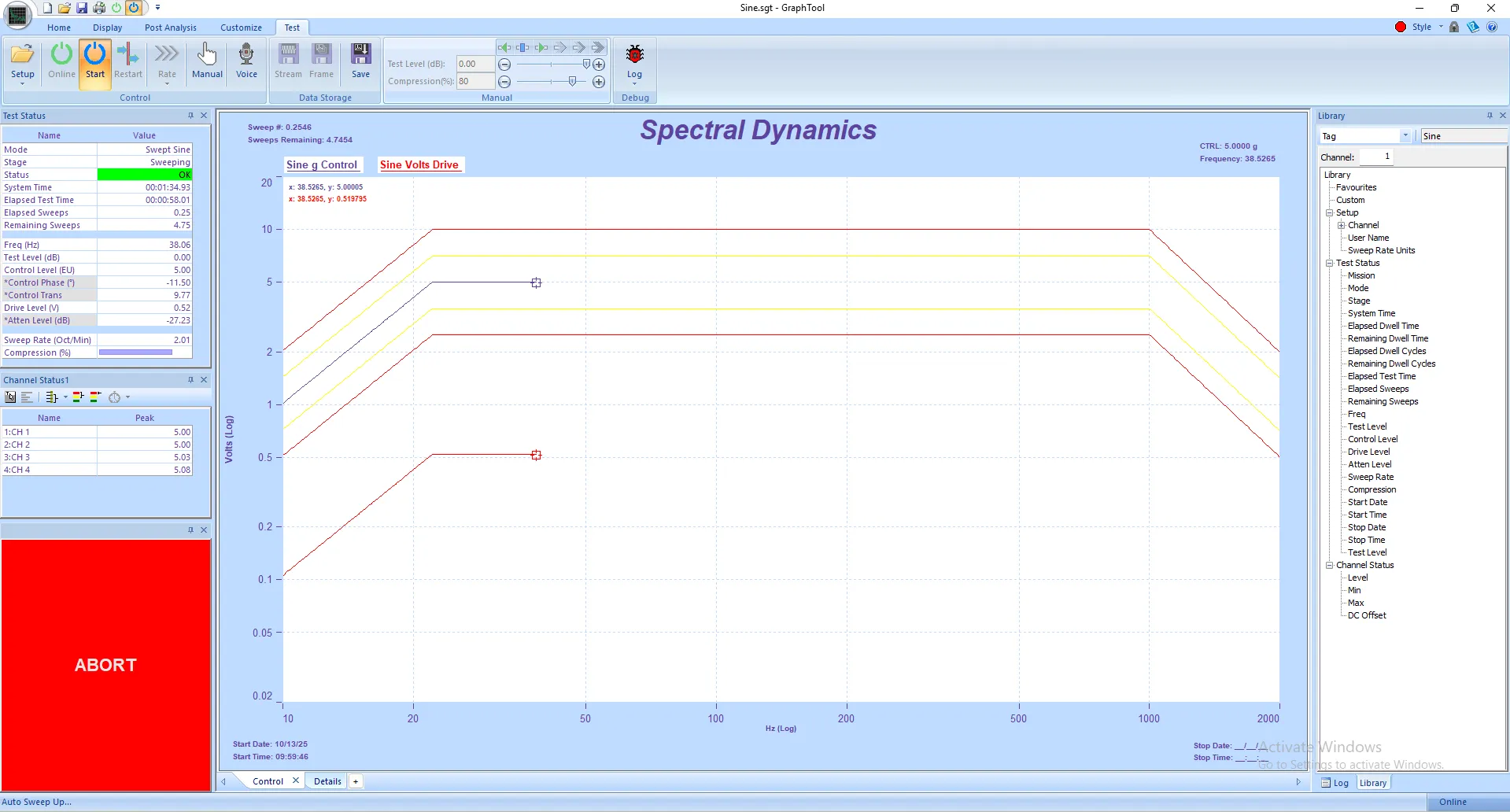

Real-World Vibration Testing Applications: When Multiple Sample Rates Matter

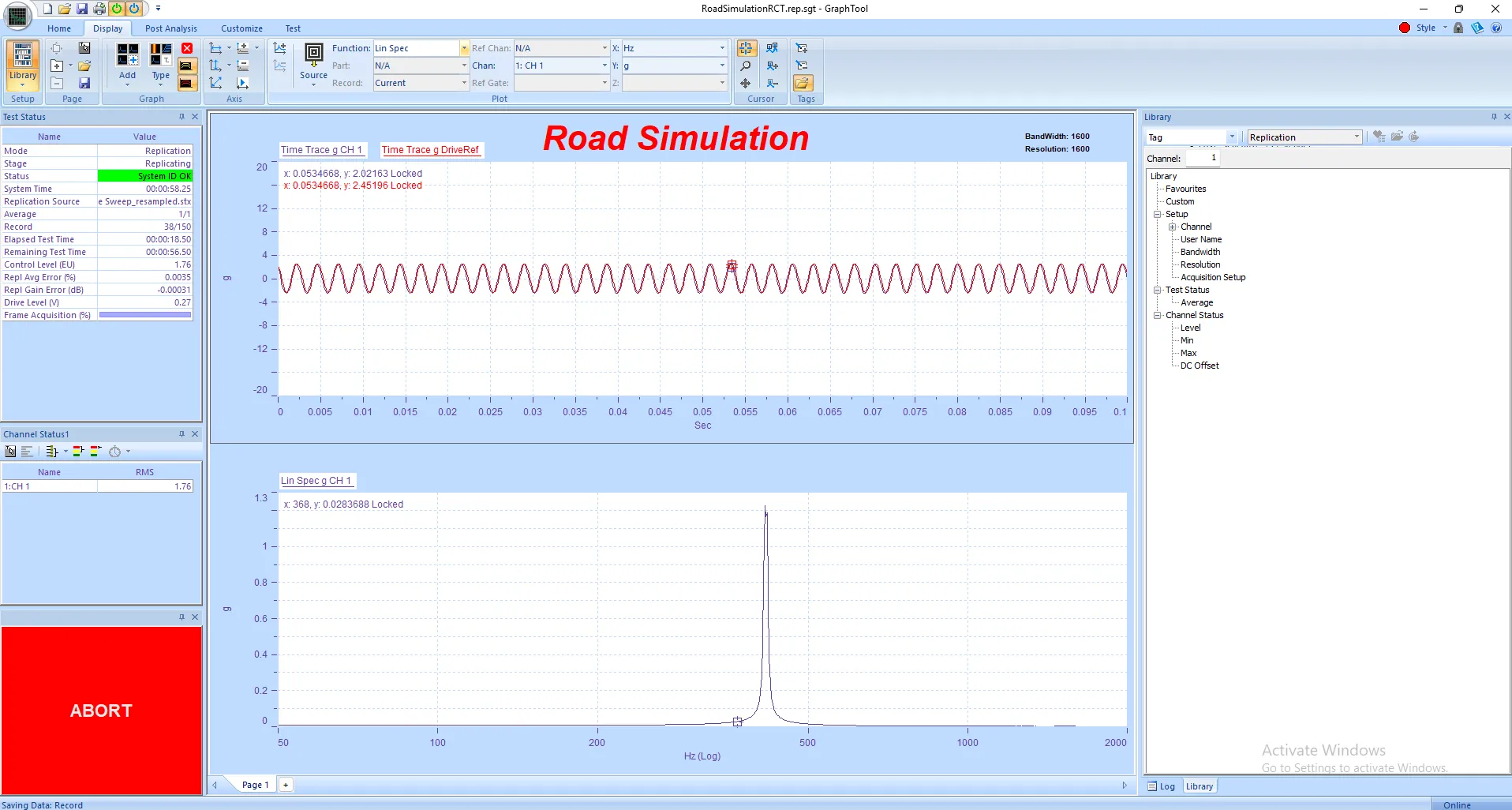

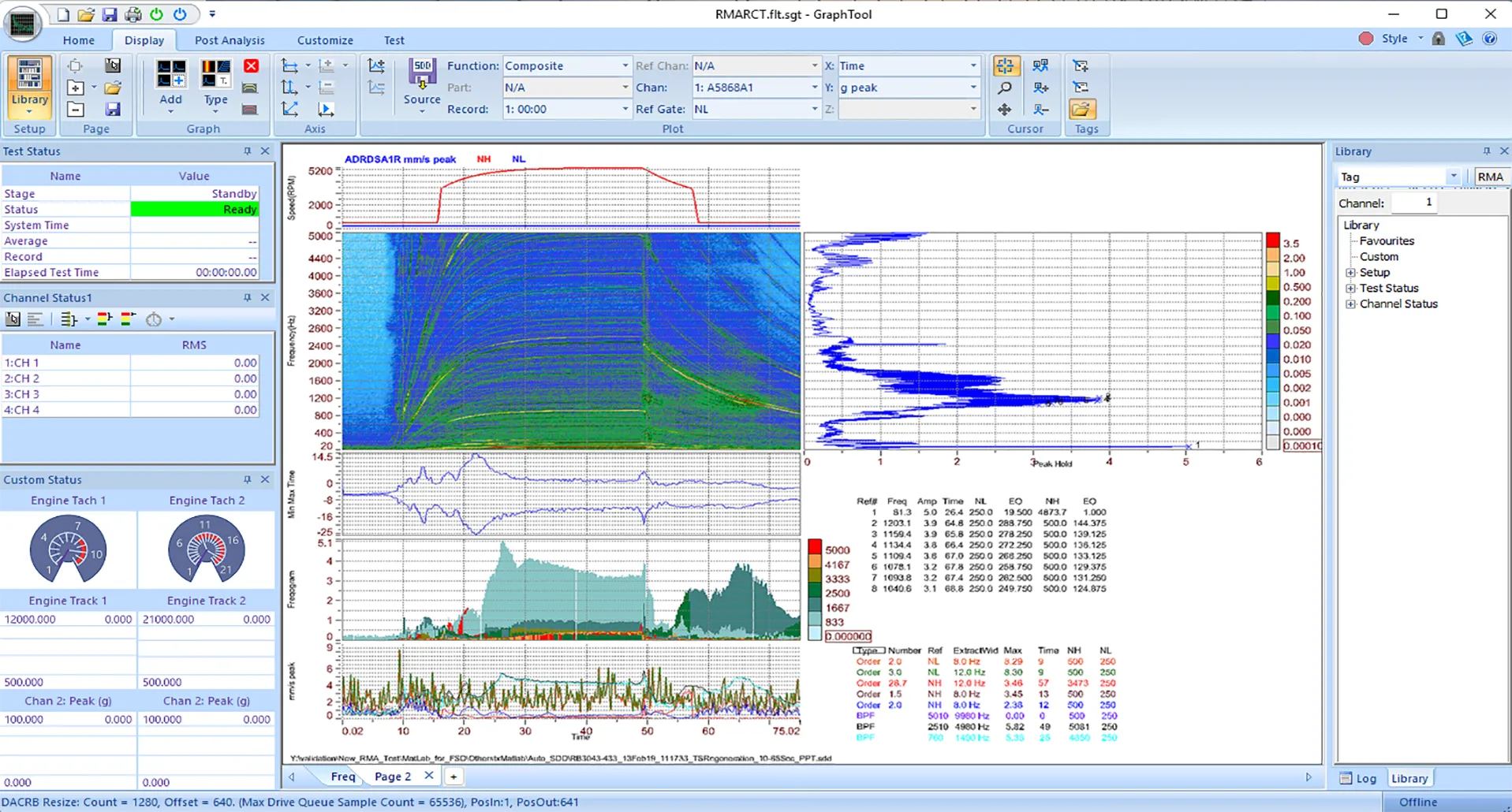

Rotating Machinery Vibration Analysis (RMA) with Mixed Sensor Types

During run-up and coast-down testing of turbomachinery, compressors, and rotating equipment:

- Primary Stream (25.6 kHz): High-speed vibration accelerometers capturing bearing frequencies, blade-pass frequencies, and harmonic analysis

- Secondary Stream 1 (6.4 kHz): Mid-speed proximity probes monitoring shaft displacement and rotor dynamics

- Secondary Stream 2 (100 Hz): Tachometer signal, oil temperature, bearing temperature, and oil pressure sensors for machinery health monitoring

This configuration allows comprehensive rotating machinery analysis without generating terabytes of unnecessary temperature data sampled at 25 kHz. The specific sample rates shown are examples—you would select the optimal rates from your system's available options based on your sensor bandwidth requirements and vibration analysis needs.

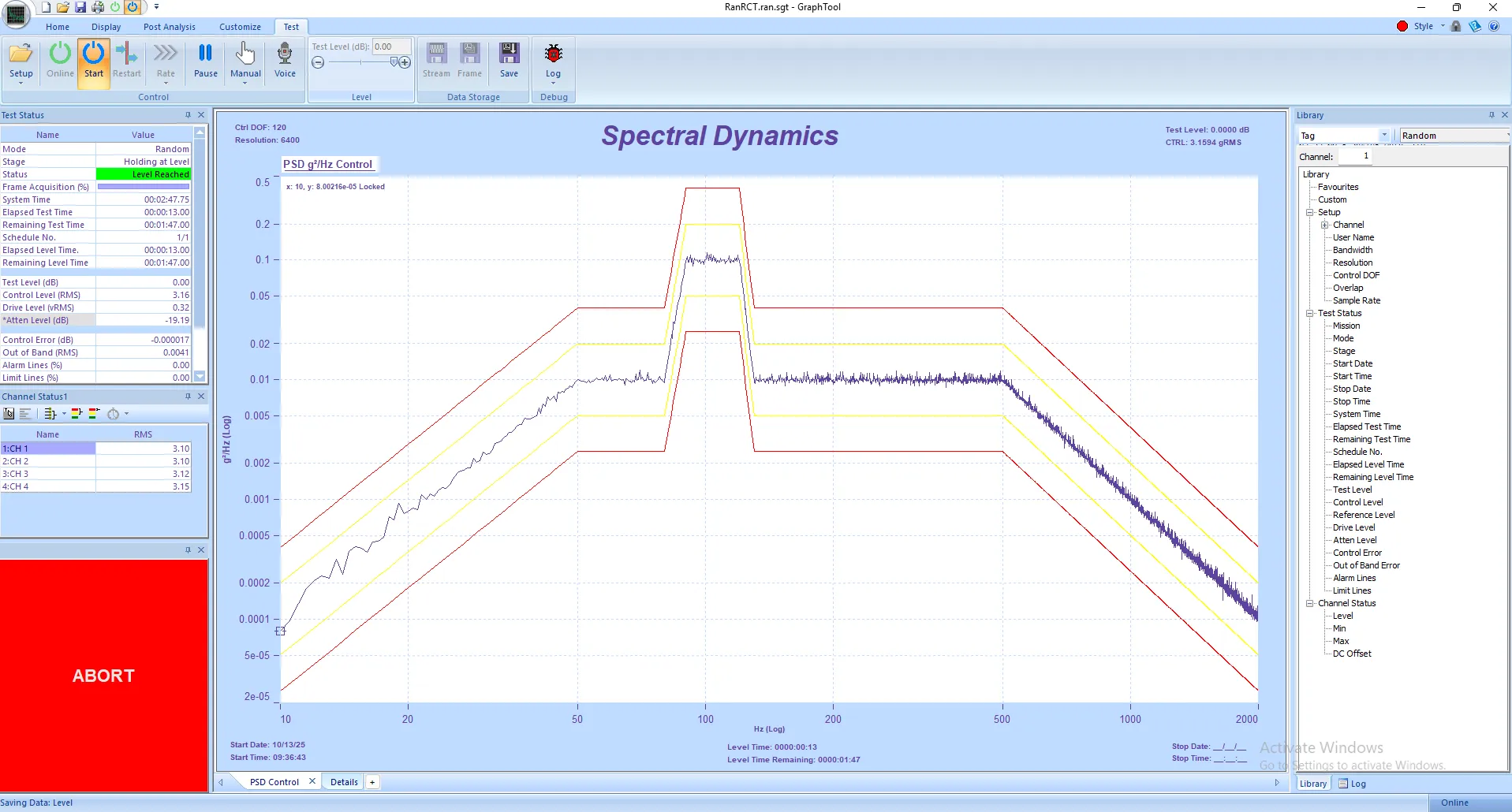

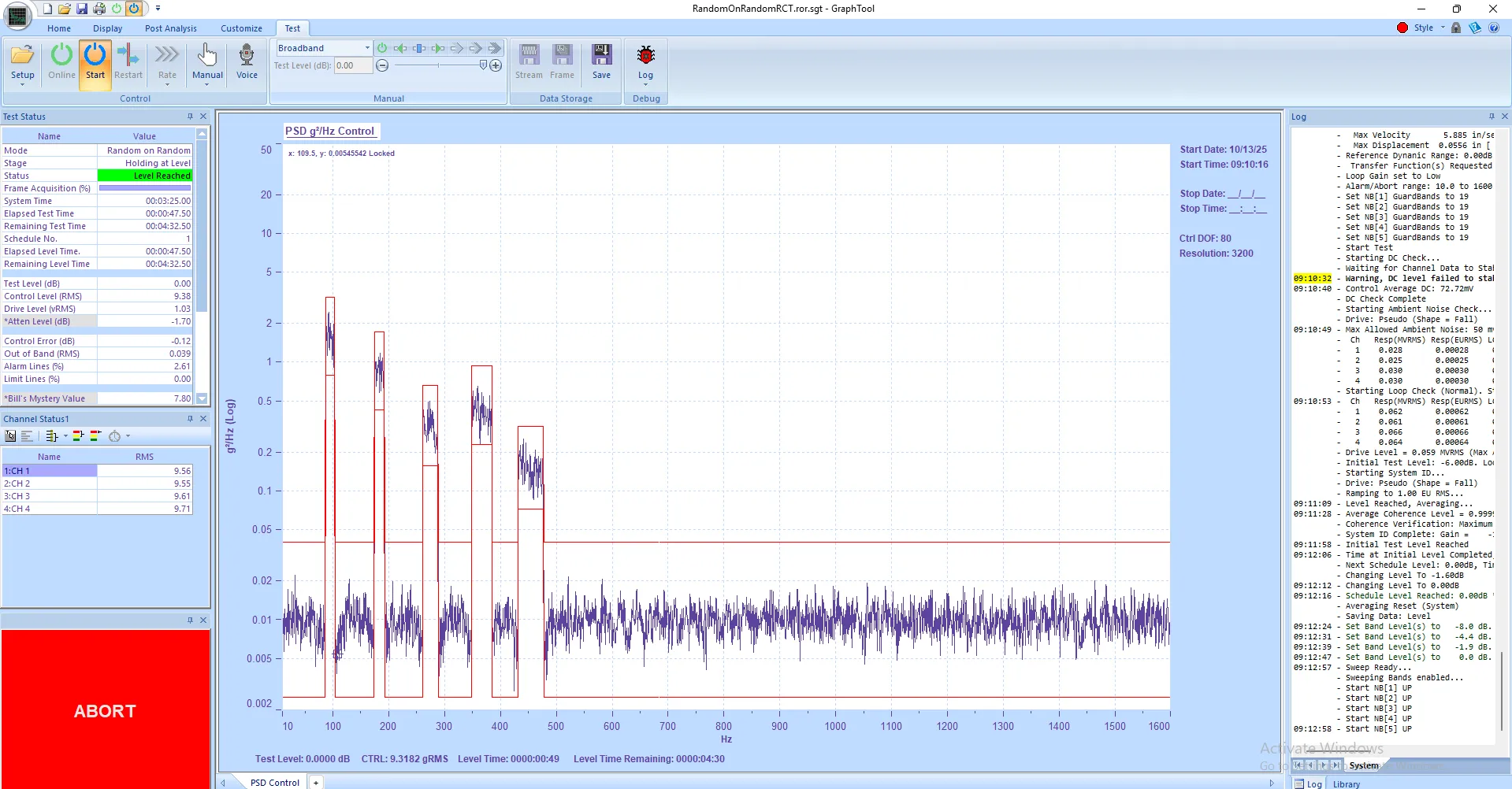

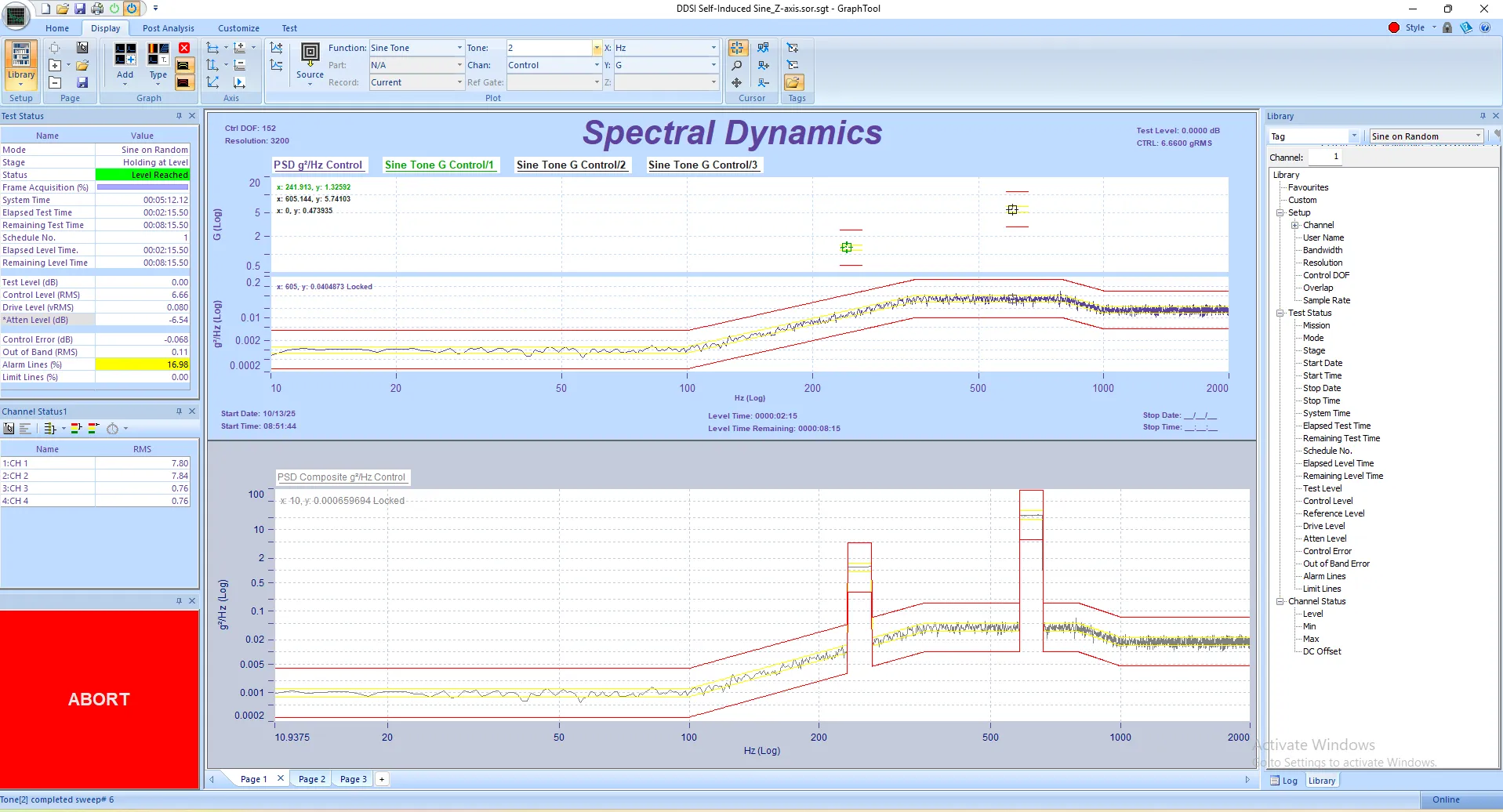

Combined Environment Vibration Testing (HALT/HASS Testing)

For qualification testing combining vibration with thermal and altitude exposure:

- Primary Stream (e.g., 12.8 kHz): Control accelerometers and critical vibration response measurements

- Secondary Stream 1 (e.g., 400 Hz): Strain gauges monitoring structural stress and fatigue

- Secondary Stream 2 (e.g., 10 Hz): Chamber temperature, altitude, humidity, and DUT power consumption

Environmental parameters change slowly and require only low-bandwidth monitoring, while vibration response demands high sample rates for accurate spectrum analysis. Multiple streams optimize both data quality and file size. Sample rates are configurable to match your specific sensor requirements—the values shown represent one typical configuration.

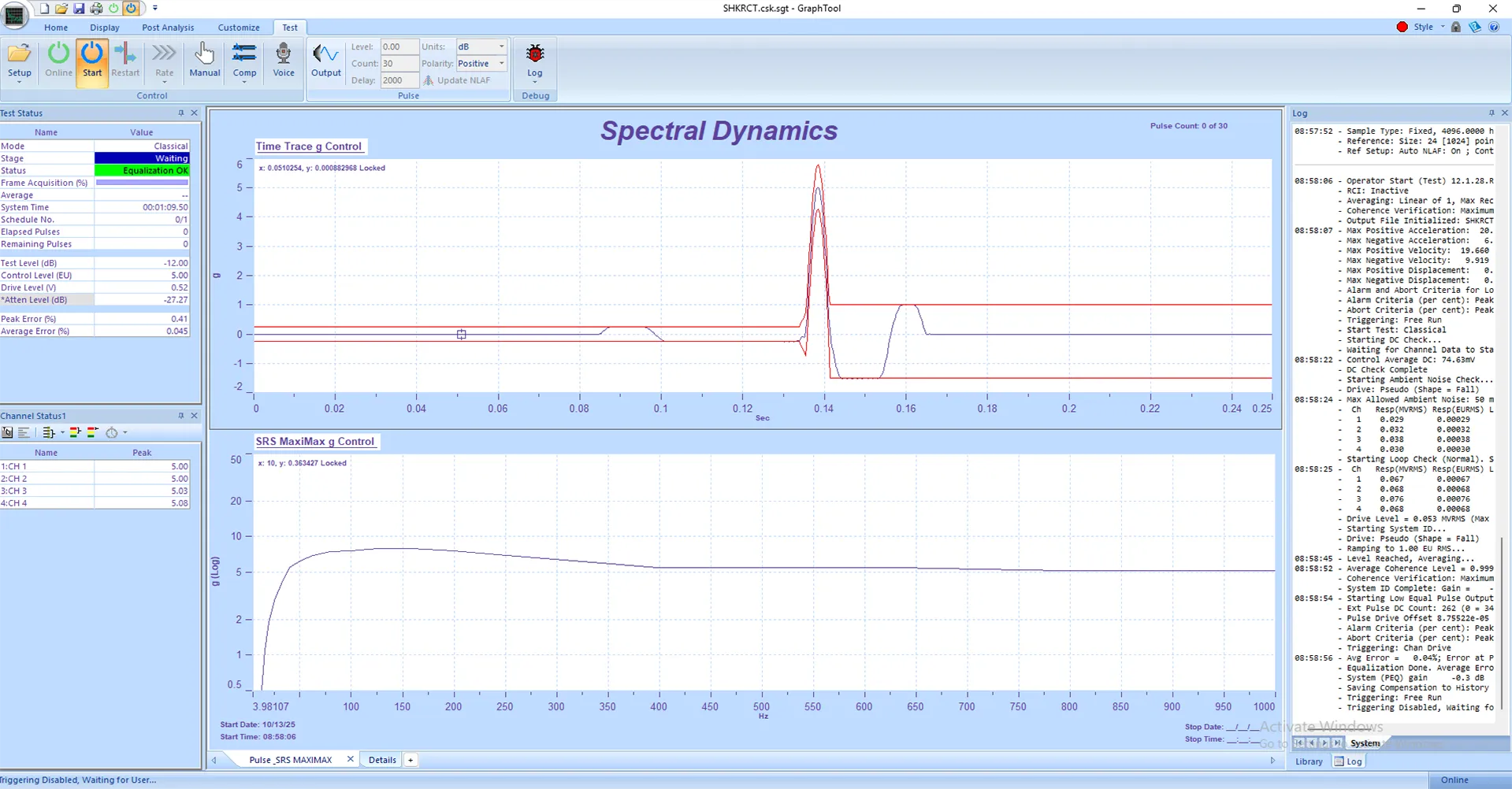

Shock Testing with Continuous Monitoring and SRS Analysis

Classical shock testing, mechanical shock, and SRS (Shock Response Spectrum) testing benefit from multiple acquisition streams:

- Primary Stream (e.g., 262 kHz): Shock accelerometers capturing high-frequency transients with maximum bandwidth for accurate SRS calculations

- Secondary Stream 1 (e.g., 6.4 kHz): Fixture and mounting point accelerometers for shock amplification analysis

- Secondary Stream 2 (e.g., 200 Hz): Continuous background monitoring between shock events for pre-test and post-test verification

The secondary stream #2 provides continuous low-rate recording documenting pre-pulse quiescence and post-pulse settling without consuming storage for high-speed data during idle periods. As with all stream configurations, you select the optimal sample rates from your system's available options.

Aerospace & Defense Applications

Multiple stream capability is essential for: Satellite vibration testing, missile component qualification, avionics testing, aircraft component vibration analysis, and MIL-STD-810 environmental stress screening where different sensor types require dramatically different sample rates.

Competitive Advantage: Why Single Sample Rate Systems Create Compromises

Most vibration controllers in the market impose a single sample rate across all channels. This fundamental limitation forces compromises:

- Over-sampling slow channels wastes massive storage space (GB per hour of unnecessary data)

- Under-sampling fast channels loses critical high-frequency information for shock and transient analysis

- Requiring multiple DAQ systems creates synchronization challenges and workflow complexity

- Compromised control performance when trying to balance conflicting requirements

PANTHER eliminates these compromises through true hardware-level support for independent streams. This is not a software workaround—it's fundamental architecture that provides:

- Optimal data quality on every channel without compromise

- Minimal storage requirements (record only what you need at the rate you need)

- Single integrated system eliminating synchronization issues between separate instruments

- Simplified workflow with all data in unified file formats for vibration analysis software

- Perfect time correlation across all streams for post-processing and correlation analysis

- Complete flexibility to configure each stream's sample rate from available system options

Data Storage Optimization: Reducing Vibration Test Data Volume by 50-70%

The storage savings from multiple independent sample rate streams can be dramatic. Consider a 24-hour endurance vibration test:

Example: Rotating Machinery 24-Hour Endurance Test

Test Configuration:

- 16 high-speed vibration channels (bearings, casing) at 25.6 kHz

- 8 mid-speed proximity probes (shaft displacement) at 6.4 kHz

- 16 low-speed sensors (temperature, pressure, power) at 10 Hz

Storage Comparison:

Single Rate System (all at 25.6 kHz): ~443 GB for 24 hours

PANTHER Multi-Stream: ~50 GB for 24 hours

Savings: 393 GB (89% reduction)

The PANTHER configuration captures all necessary vibration data with full fidelity while reducing storage by hundreds of gigabytes per test—critical when archiving years of qualification data. The exact savings depend on your selected sample rates, but reductions of 50-70% are typical for multi-sensor vibration testing applications.

Configuration Guide: Setting Up Multiple Data Acquisition Streams

Step 1: Define Stream Requirements Based on Sensor Bandwidth

Before configuring streams, determine bandwidth requirements for each channel type:

- Control channels and critical response measurements: Match application bandwidth (typically 10-25 kHz for vibration control)

- Structural response (strain, displacement): Typically 1/4 to 1/2 control bandwidth (3-12 kHz)

- Environmental sensors (temperature, pressure): 10-100 Hz sufficient

- Tachometer and trigger signals: Depends on maximum expected frequency (2-10 kHz typical)

Step 2: Configure Input Types and Sample Rates in GTX Software

In the GTX vibration control software Setup menu, navigate to Set Input Type. The default configuration uses a single Primary Stream. To enable multiple acquisition streams:

- Select channels to assign to Secondary Stream 1

- Optionally select channels for Secondary Stream 2

- Configure sample rate/bandwidth for each stream independently—select from any available sample rate on your PANTHER system

- Verify anti-aliasing filter settings for each stream match the selected sample rate

Important: Each secondary stream can use any sample rate available on your PANTHER system that is equal to or lower than your base (primary) sample rate. This gives you complete flexibility to optimize data quality and storage for each measurement type.

Step 3: Optimize FFT Frame Size and Overlap for Each Stream

Each stream can have independent frame processing parameters:

- Primary Stream: Frame size optimized for control loop latency (typically 1024-4096 points for fast response)

- Secondary Streams: Frame size can be larger for better frequency resolution (4096-16384 points) since these streams don't affect control loop response time

Step 4: Enable Gap-Free Streaming and Recording

PANTHER's gap-free streaming works across all acquisition streams simultaneously:

- Enable "Stream to Disk" in the vibration test setup

- All streams record continuously with synchronized timestamps

- Each stream creates its own data file with optimized format

- Post-test analysis tools automatically correlate all streams

Best Practices for Multi-Stream Vibration Data Acquisition

Match Sample Rates to Physical Sensor Bandwidth

Sampling at 10x the sensor bandwidth is generally sufficient for accurate vibration measurements. Examples:

- Accelerometer (DC-5 kHz): 50 kHz minimum (typically use 51.2 kHz or 25.6 kHz with 2.5x factor)

- Proximity probe (DC-1 kHz): 10 kHz minimum (typically use 12.8 kHz or 6.4 kHz)

- Thermocouple (DC-1 Hz): 10 Hz sufficient (typically use 10 Hz or 100 Hz)

- Strain gauge (DC-500 Hz): 5 kHz minimum (typically use 6.4 kHz or 3.2 kHz)

Organize Channels by Measurement Function

Group streams around measurement purposes:

- Primary Stream: Control sensors and safety abort channels requiring fastest response and control loop integration

- Secondary Stream 1: Response measurements for test article characterization and structural analysis

- Secondary Stream 2: Environmental and ancillary measurements (temperature, pressure, DC signals)

Consider Post-Processing and Vibration Analysis Requirements

If you plan correlation analysis between streams, ensure:

- All streams have sufficient sample rate for time-correlation (typically 2x highest frequency of interest)

- Frame timing is coordinated (use compatible frame sizes for coherence analysis)

- Trigger channels are recorded on appropriate stream for synchronization verification

Balance Frequency Resolution vs. Update Rate

Remember that frequency resolution, update rate, and overlap are interrelated:

Higher spectral resolution = larger FFT frame size = slower update rate (or requires more overlap)

For example with 25.6 kHz sample rate:

- 1024-point FFT = 25 Hz resolution, 25 updates/sec (no overlap)

- 4096-point FFT = 6.25 Hz resolution, 6.25 updates/sec (no overlap)

- 4096-point FFT = 6.25 Hz resolution, 12.5 updates/sec (50% overlap)

Secondary streams not involved in vibration control can use larger FFT frames for better frequency resolution without impacting system responsiveness.

Technical Specifications: Multi-Stream Data Acquisition Capability

| Parameter | Specification |

|---|---|

| Maximum Number of Streams | Up to 3 independent streams (Primary + 2 optional secondary) |

| Sample Rate Configuration | User-selectable from available system sample rates; secondary streams can use any rate ≤ primary stream rate |

| Time Synchronization | All streams phase-locked with <1 µs timing accuracy |

| Available Sample Rates | System-dependent; typically includes 100 Hz to 262.144 kHz in standard octave intervals (100, 200, 400, 800, 1600, 3200, 6400, 12800, 25600, 51200, 102400, 262144 Hz) |

| Anti-Aliasing Filters | Independent selection per stream: 1 kHz, 10 kHz, 25 kHz, or OFF |

| Recording Format | Gap-free streaming to disk with synchronized timestamps across all streams |

Summary: PANTHER Multi-Stream Advantage for Advanced Vibration Testing

PANTHER's multiple acquisition streams capability represents a fundamental technological advantage that competitors cannot match through software alone. By providing true hardware-level support for user-configurable independent sample rates across up to three concurrent streams, PANTHER enables:

- Optimal data quality on every channel—no compromises between different measurement requirements

- Dramatic storage reduction (50-70% typical) compared to single-rate vibration control systems

- Simplified test setup—one integrated system replaces multiple data acquisition boxes

- Perfect time synchronization across all streams for confident correlation analysis and modal analysis

- Flexible configuration adapting to any test scenario from simple sine sweeps to complex multi-axis shock testing

- Complete freedom to select optimal sample rates from your system's available options

Whether testing rotating machinery with mixed sensor types, conducting combined environment qualification (HALT/HASS), performing shock testing with continuous monitoring, or executing complex aerospace vibration requirements, PANTHER's multiple streams capability optimizes both data quality and operational efficiency. With user-selectable sample rates for each stream, you maintain complete control over your vibration data acquisition strategy.