Overview: Automating Complex Test Sequences with RCI

PANTHER's Remote Control Interface (RCI) option enables seamless automation between your vibration controller and external test equipment such as environmental chambers, data acquisition systems, and other test instruments. Using TTL (Transistor-Transistor Logic) digital signals through a USB interface box, RCI allows bidirectional communication that orchestrates complex test sequences without operator intervention.

PANTHER's Remote Control Interface (RCI) option enables seamless automation between your vibration controller and external test equipment such as environmental chambers, data acquisition systems, and other test instruments. Using TTL (Transistor-Transistor Logic) digital signals through a USB interface box, RCI allows bidirectional communication that orchestrates complex test sequences without operator intervention.

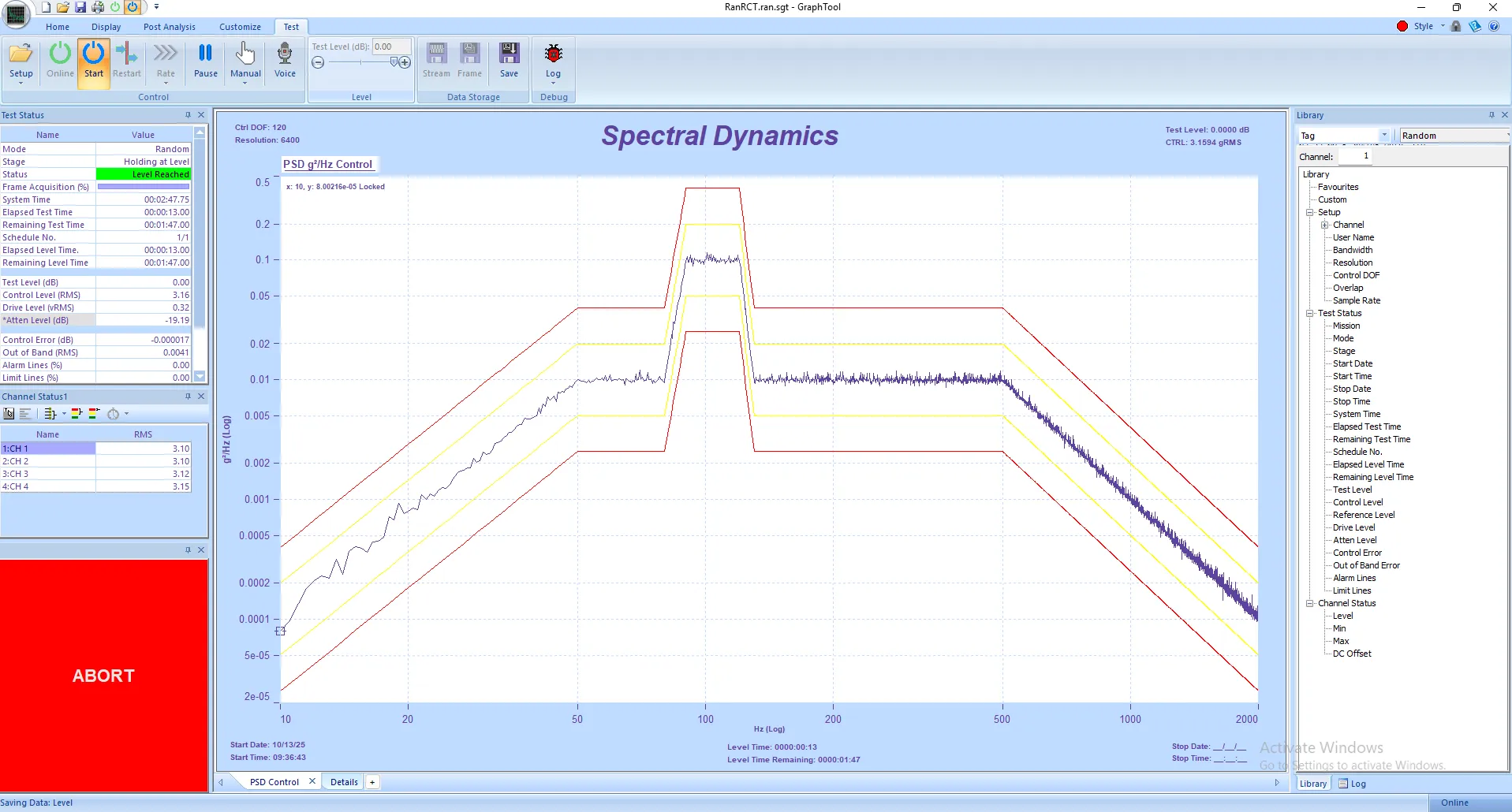

When a PANTHER vibration test completes, RCI can automatically signal an environmental chamber to begin its thermal cycle. Conversely, when a chamber reaches target temperature, it can signal PANTHER to start the next vibration test. This capability is essential for combined environment testing, HALT/HASS qualification, and any multi-stage test protocol requiring coordination between different instruments.

Key RCI Capabilities

- 16 TTL input lines for receiving commands from external equipment

- 16 TTL output lines for sending status signals to external equipment

- USB connectivity for simple computer connection

- Configurable actions based on digital signal state changes (high/low)

- Support for complex event-driven test automation

How RCI Works: Hardware Connection & Signal Flow

The RCI hardware consists of a USB interface box that connects to your PANTHER control computer via USB cable. The computer recognizes the RCI device as a COM port in Device Manager. External equipment connects to the RCI box through standard ribbon cables—one for inputs and one for outputs. Each direction (input and output) provides 16 independent digital lines for maximum flexibility.

RCI Input Configuration: External Equipment Controls PANTHER

RCI inputs allow external devices to trigger specific actions in PANTHER by changing a digital line's state from high to low or low to high. When an environmental chamber completes its soak phase, for example, it can pull an input line high, triggering PANTHER to automatically start a pre-loaded vibration test.

Configurable Input Actions Include:

- Start Test: Begin a loaded vibration test

- Stop Test: Cleanly stop the running test

- Abort Test: Immediately abort the test

- Full Level: Set test to full specified level

- Resume: Resume a paused test (or pause if already running)

- Load Test: Load a specific test file when no test is running

- Online: Toggle system online/offline (Analysis applications)

- Log Message: Record custom message in PANTHER log without performing action

Each of the 16 input lines can be independently configured with different actions for line-high and line-low transitions. You can even specify which test file to load when using the "Load Test" action, enabling automatic cycling through multiple test configurations.

RCI Output Configuration: PANTHER Reports Status to External Equipment

RCI outputs allow PANTHER to communicate its current status to external equipment by changing output line states. When a vibration test completes, PANTHER can set specific output lines high or low, signaling connected equipment (like an environmental chamber) to proceed with the next phase of testing.

System Events That Trigger Output Changes:

- Test Started: Vibration test begins

- Test Stopped: Test completes normally

- Test Aborted: Test aborted due to limit violation or operator intervention

- Test Paused/Resumed: Test temporarily suspended or continued

- Level Changes: Test reaches equalization or full level

- Schedule Transitions: Multi-level test advances to next schedule segment

For each system event, you can specify which output lines change state and whether they go high or low. Multiple lines can be set simultaneously using comma-separated lists or ranges (e.g., "1,3-5" sets lines 1, 3, 4, and 5). Output line states persist until changed by another event, providing reliable status indication to connected equipment.

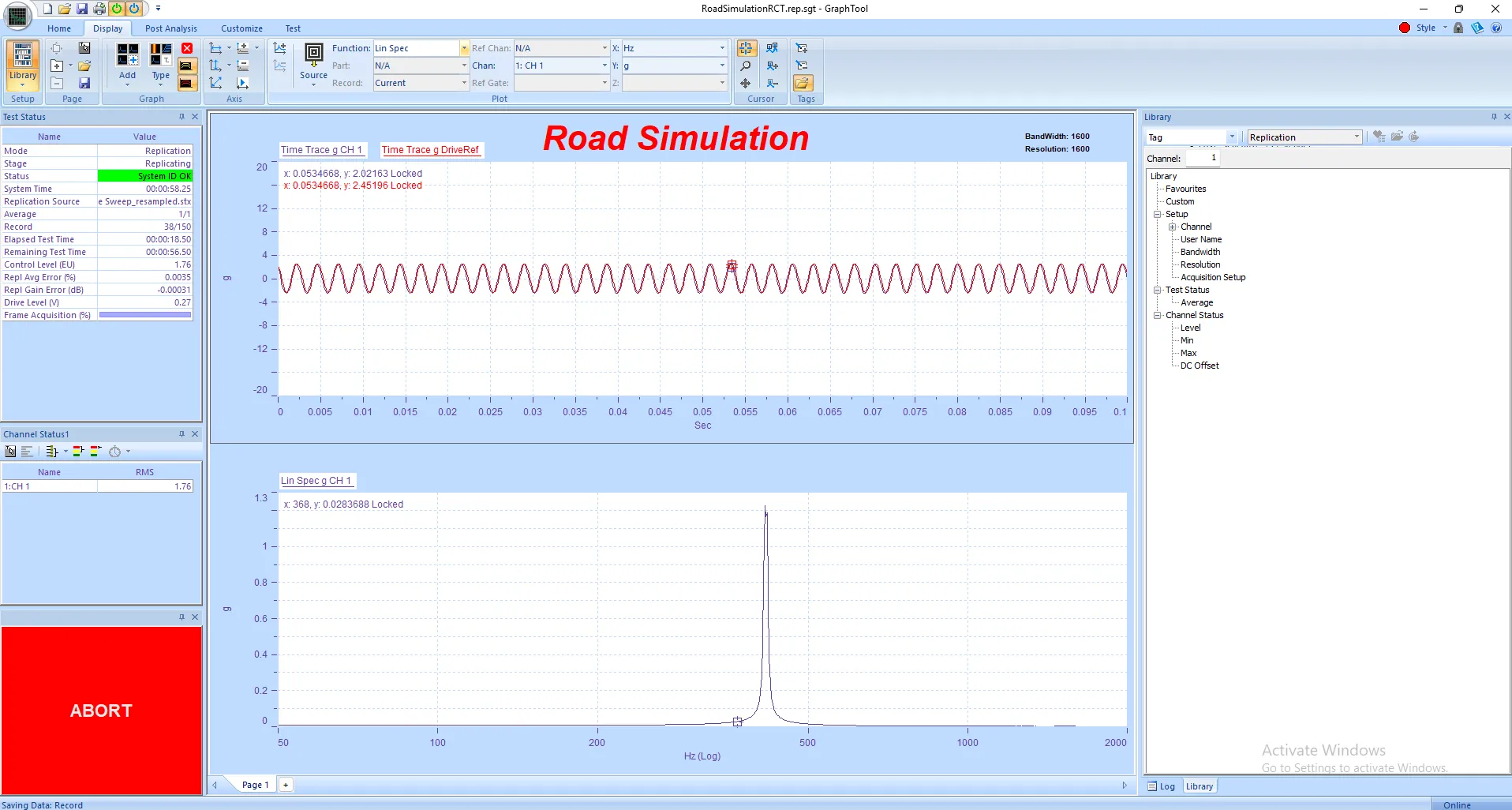

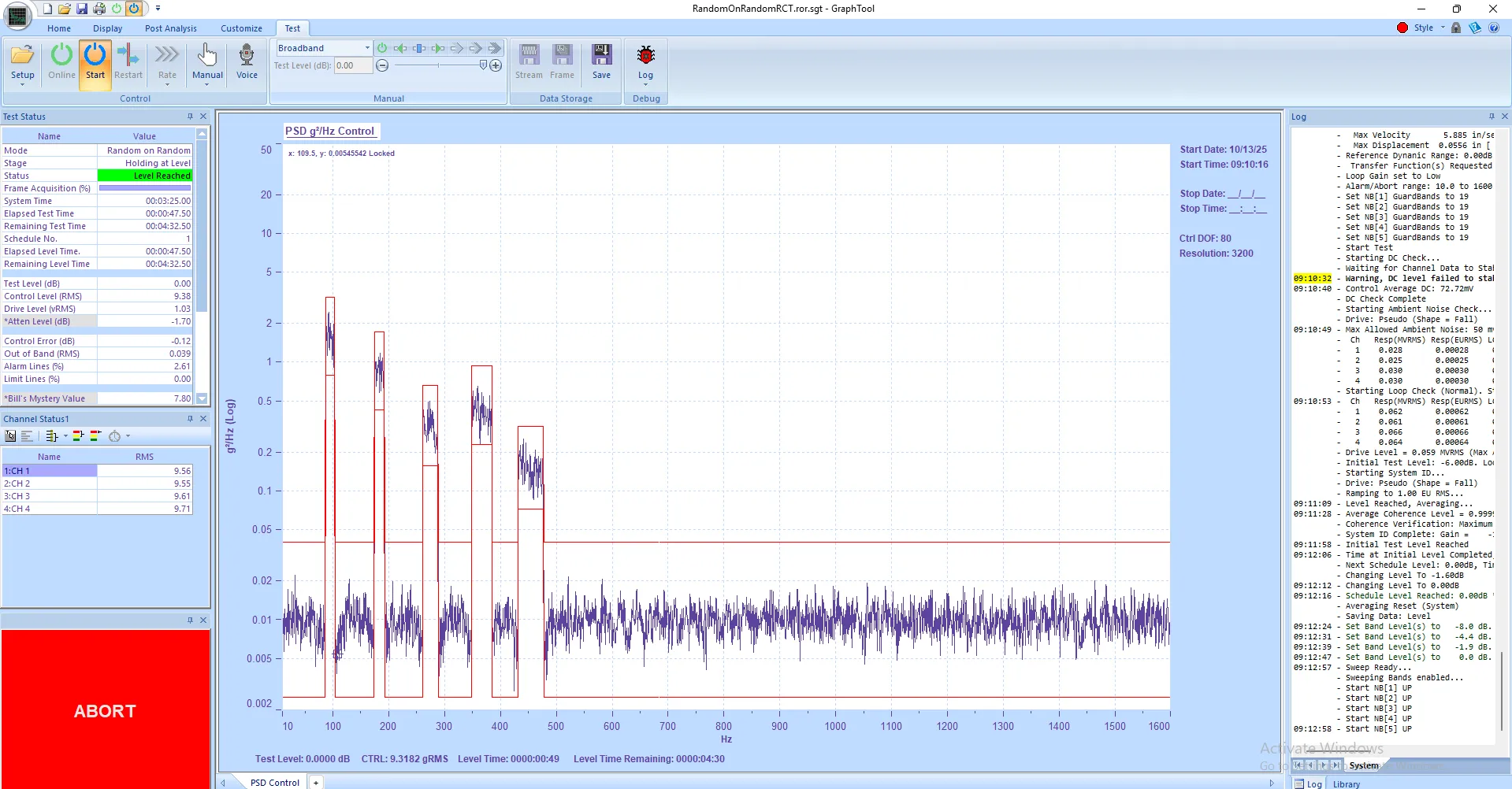

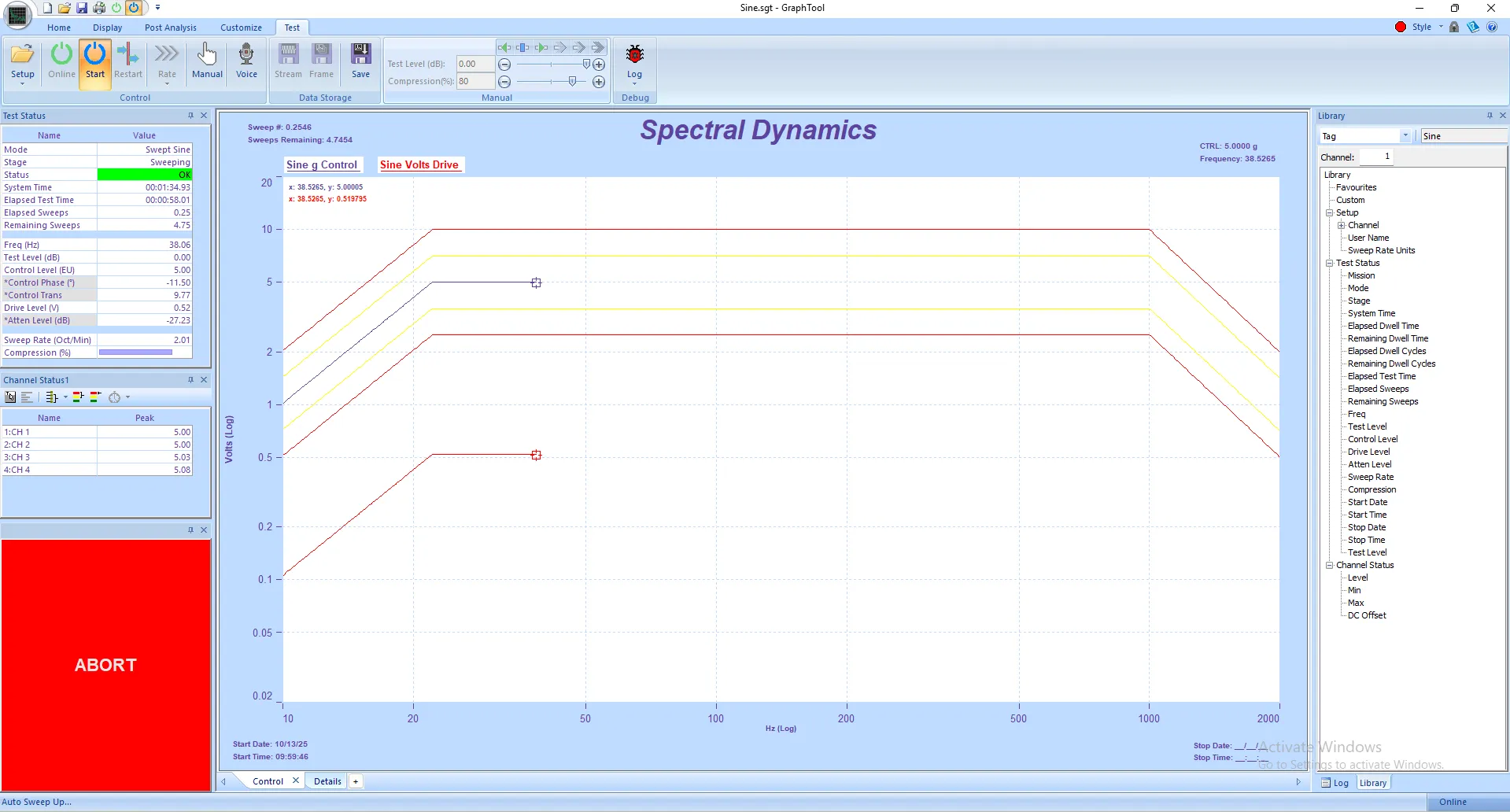

Real-World Applications: Combined Environment Testing Automation

Automated HALT/HASS Testing with Thermal Chamber Integration

Consider a HALT (Highly Accelerated Life Test) protocol requiring alternating thermal and vibration stress:

Test Sequence:

- Chamber ramps to hot extreme temperature

- Chamber reaches target, sends "ready" signal via RCI input → PANTHER starts vibration

- PANTHER completes vibration dwell, sends "complete" signal via RCI output → Chamber begins cold ramp

- Chamber reaches cold extreme, sends "ready" signal → PANTHER starts vibration

- Cycle repeats automatically until programmed number of cycles completes

Without RCI, an operator must manually monitor both instruments and coordinate transitions. With RCI, the entire sequence runs unattended overnight or over weekends, dramatically improving test throughput and eliminating timing errors.

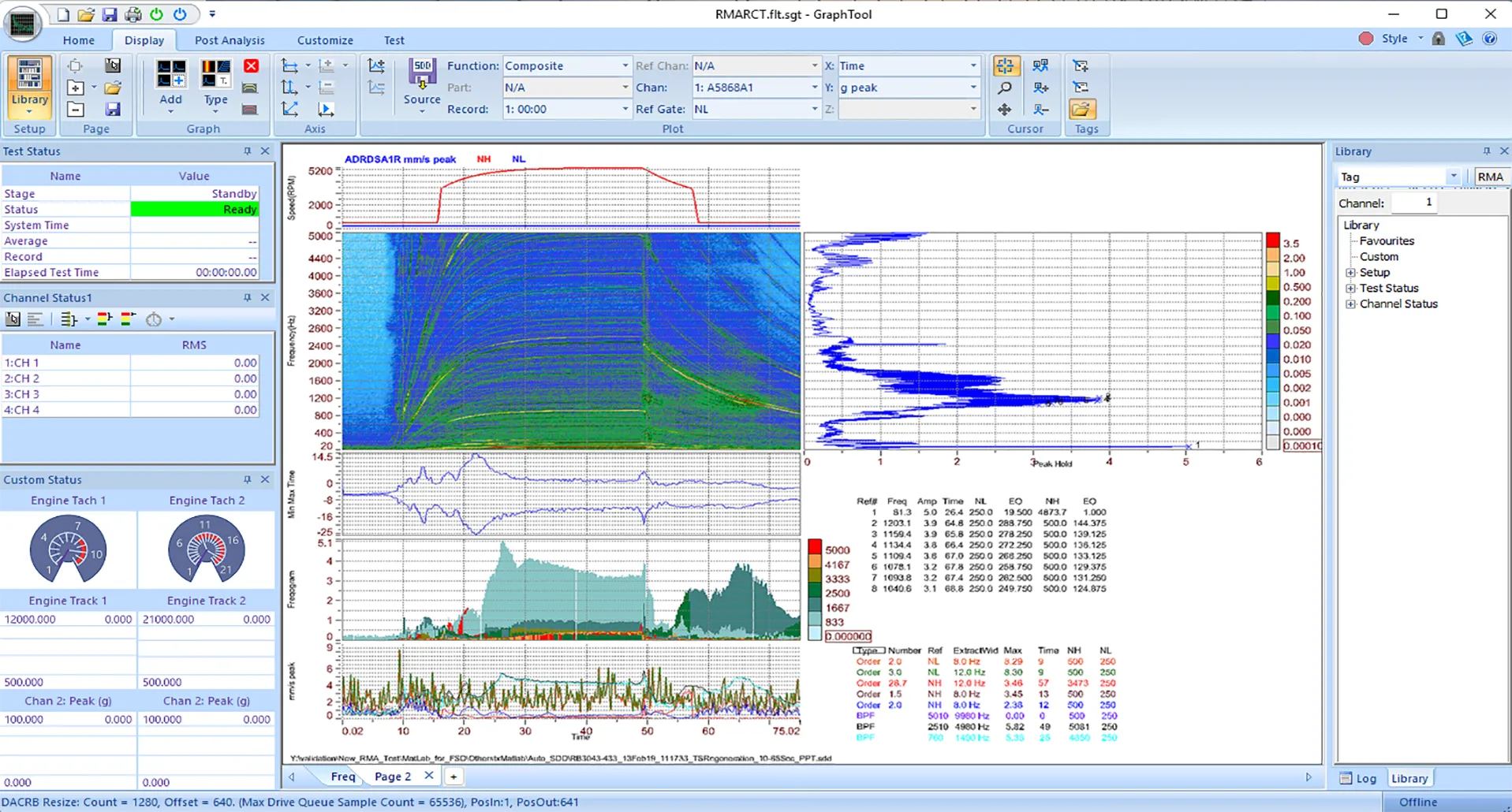

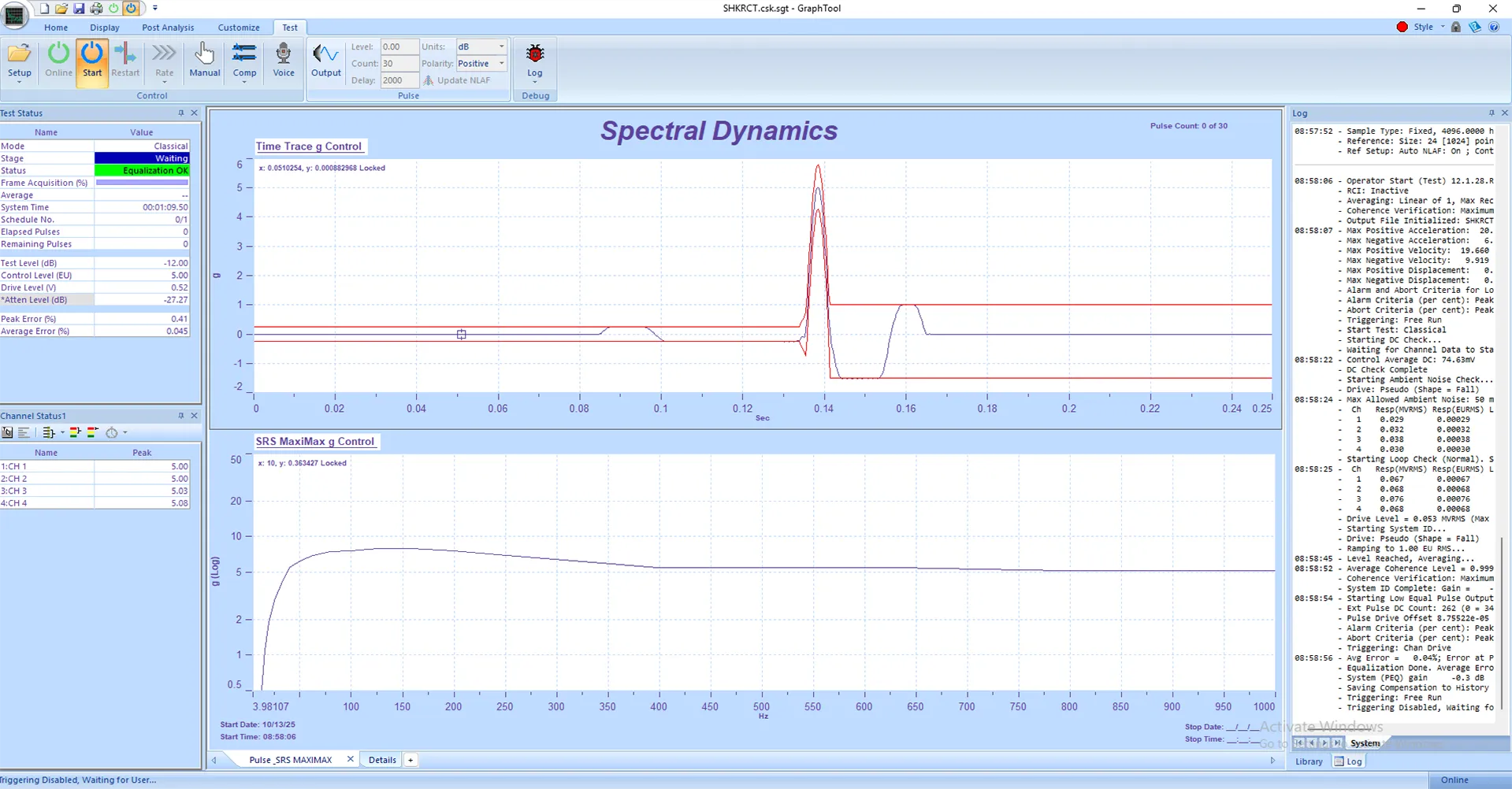

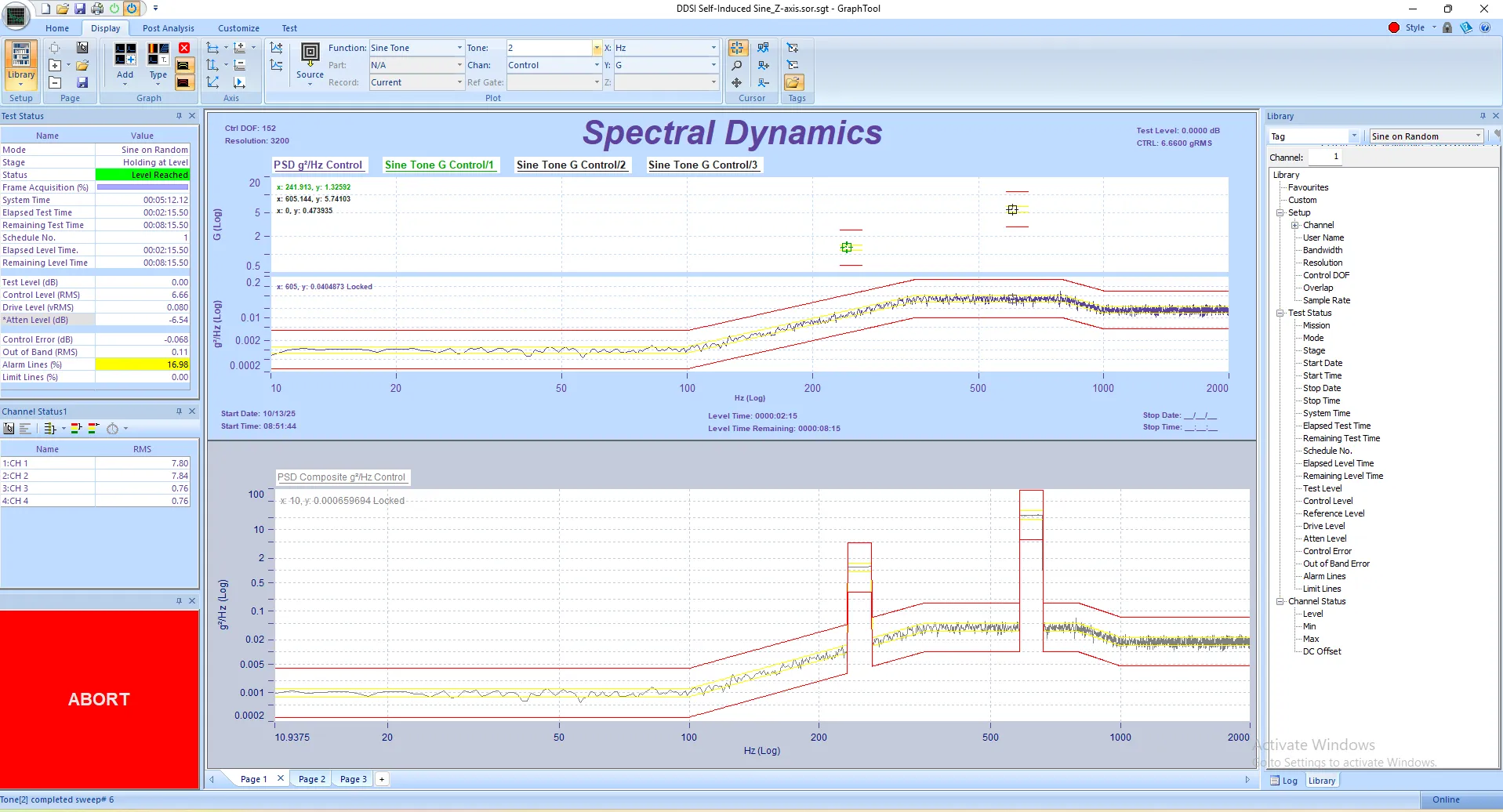

Multi-Axis Test Coordination

When testing with multiple PANTHER systems (e.g., tri-axial testing with three single-axis shakers), RCI enables synchronized test sequences. System 1 completes its X-axis profile and signals System 2 to begin Y-axis testing. System 2 completion triggers System 3 for Z-axis testing. All three systems coordinate automatically without operator intervention.

Data Acquisition Triggering

RCI outputs can trigger external high-speed data acquisition systems to capture transient events during vibration testing. When PANTHER detects a resonance or applies a shock pulse, RCI signals the DAQ system to begin recording, ensuring synchronized data capture without pre-triggering or missing critical events.

Aerospace & Defense Applications

RCI is essential for MIL-STD-810 and similar protocols requiring multiple environmental stressors applied in specific sequences. Altitude chambers, thermal chambers, humidity chambers, and vibration controllers can be orchestrated into fully automated qualification test sequences matching standard test methods.

RCI Configuration: Setup Process in Panther Software

Accessing the Remote Control Interface Dialog

In PANTHER's main menu, navigate to Setup → Remote Control Interface to access the RCI configuration dialog. The dialog provides separate tabs for RCI Input setup and RCI Output setup, with intuitive menus for saving/loading configurations and inverting logic if needed.

Configuring RCI Inputs

For each of the 16 input lines, specify:

- Action on High: What PANTHER does when line goes high

- Action on Low: What PANTHER does when line goes low

- Test File: Which test to load (if using "Load Test" action)

- Log Message: Custom message recorded when action occurs

Actions can be identical for high and low transitions, meaning the action executes whenever the line state changes. The "Invert RCI-In Lines" option in the Options menu reverses high/low logic if your external equipment uses opposite polarity.

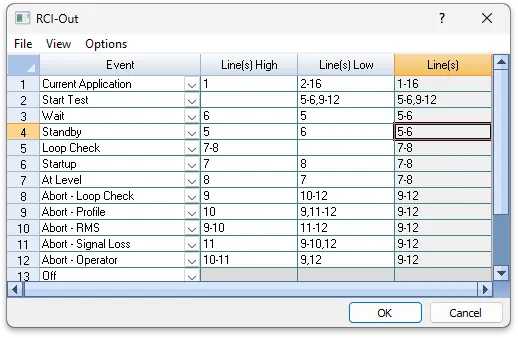

Configuring RCI Outputs

For each system event, specify:

- Lines High: Which output lines to set high (comma-separated or range notation)

- Lines Low: Which output lines to set low

The configuration dialog displays which lines will be modified by each event, making it easy to verify that different events don't conflict. For example, you might use lines 1-4 for test status, lines 5-8 for level information, and lines 9-12 for error conditions.

Configuration files (.rci extension) can be saved and loaded, allowing you to create standard configurations for different test protocols and switch between them as needed.

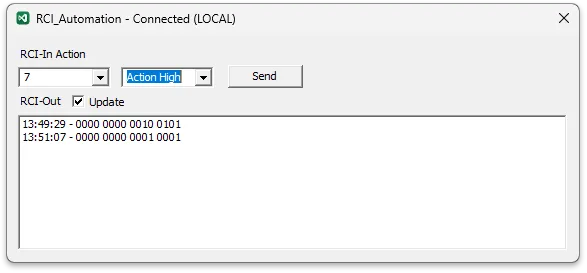

Advanced RCI: Automation SDK for Custom Applications

For users requiring programmatic control beyond simple TTL signals, PANTHER includes an RCI Automation SDK with ActiveX support. This allows custom software applications (written in Visual C++ or similar) to send RCI commands and read RCI status directly, enabling integration with laboratory information management systems (LIMS), custom test executives, or proprietary automation frameworks.

SDK Functions Include:

- ConnectT40: Establish connection to PANTHER (local or remote via IP address)

- RCICommandIn: Simulate input line state changes programmatically

- RCIStatusOut: Read current output line states

Example code and documentation are provided in the PANTHER installation directory under Program Files\Spectral Dynamics\Panther\Automation\RCI.

Technical Specifications: RCI Hardware & Connectivity

| Parameter | Specification |

|---|---|

| Number of Input Lines | 16 independent TTL inputs |

| Number of Output Lines | 16 independent TTL outputs |

| Signal Type | TTL (Transistor-Transistor Logic) digital |

| Computer Connection | USB interface (appears as COM port) |

| External Equipment Connection | Ribbon cables (separate input and output cables) |

| Configuration File Format | .rci files (saveable/loadable configurations) |

| Logic Inversion | Optional inversion of high/low logic |

| Automation Support | ActiveX SDK with C++ example code |

Benefits: Why RCI Matters for Modern Test Labs

Improved Test Throughput

Automated test sequencing eliminates the wait time between test phases. Tests can run continuously through nights and weekends, dramatically increasing equipment utilization and reducing time-to-market for product qualification.

Reduced Human Error

Manual coordination of multiple instruments is error-prone. Operators can misread status indicators, miss timing requirements, or forget protocol steps. RCI automation ensures perfect timing and sequence adherence every time.

Better Data Integrity

Automated transitions ensure environmental conditions are precisely as specified. No thermal drift between chamber stabilization and vibration test start. No timing ambiguity for correlation between environmental and vibration data.

Standards Compliance

Many test standards (MIL-STD-810, RTCA DO-160, IEC standards) specify precise timing between environmental stressors. RCI automation ensures compliance with timing requirements that would be difficult or impossible to achieve manually.

Cost Efficiency

Reducing labor requirements for test monitoring and reducing test time through automation both contribute to lower per-test costs. Equipment utilization improvements can defer capital expenditure for additional test systems.

Summary: RCI as the Foundation for Automated Test Laboratories

PANTHER's Remote Control Interface represents essential infrastructure for modern test laboratories requiring coordination between vibration controllers and other test equipment. Whether integrating with environmental chambers for HALT/HASS testing, synchronizing multiple shaker systems for multi-axis testing, or triggering data acquisition for transient capture, RCI provides the digital communication pathway necessary for fully automated test sequences.

With 16 configurable input and output lines, TTL compatibility with virtually all test equipment, and optional ActiveX automation for custom applications, RCI adapts to any test protocol while maintaining reliability critical for unattended operation. The result is higher throughput, better data quality, reduced operator workload, and improved standards compliance—all essential for competitive product development and qualification testing.