PANTHER Vibration Controller vs Other Systems: Comprehensive Comparison

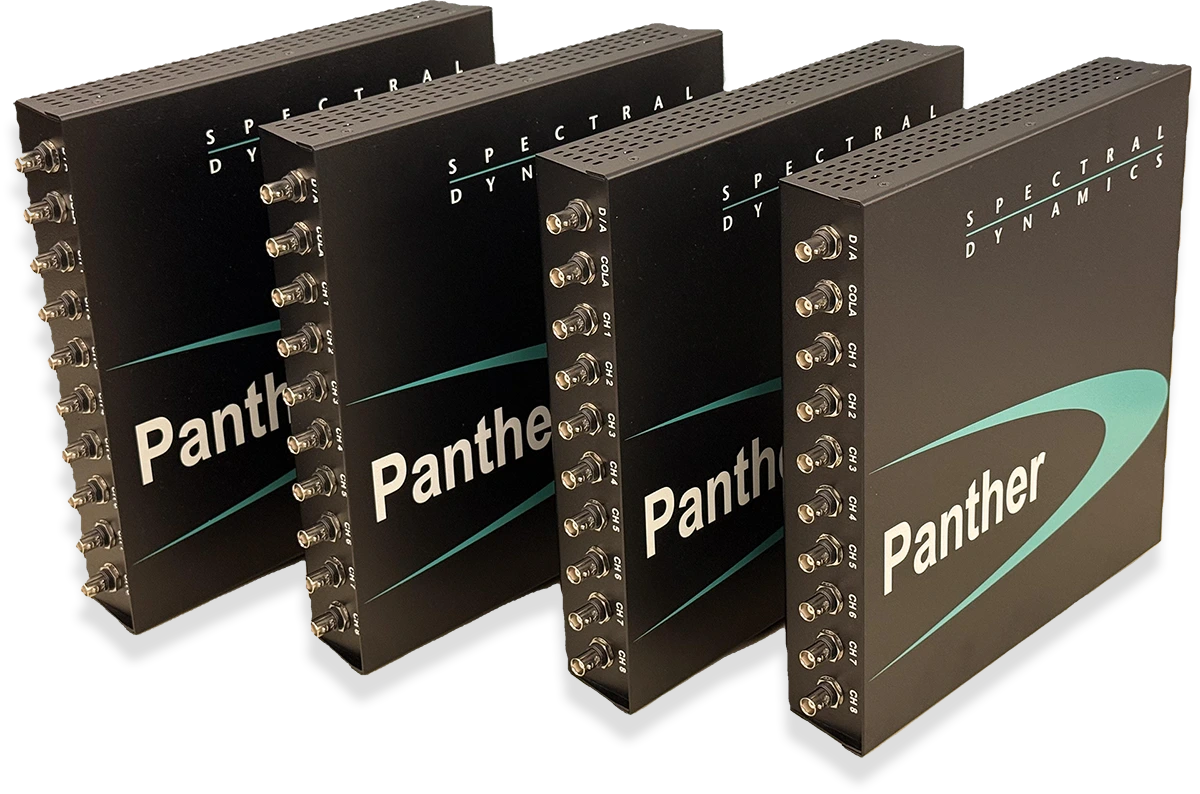

While most advanced vibration controllers employ some form of adaptive control, the Spectral Dynamics PANTHER vibration control system differentiates itself through genuine technological innovation and superior engineering. The following comparison highlights key capabilities that set PANTHER apart in the vibration testing industry.

While most advanced vibration controllers employ some form of adaptive control, the Spectral Dynamics PANTHER vibration control system differentiates itself through genuine technological innovation and superior engineering. The following comparison highlights key capabilities that set PANTHER apart in the vibration testing industry.

What Makes PANTHER Different

- Patented Adaptive Control Algorithms: Specialized, patented methods designed for superior performance across sine, random, shock, and combined test types

- Exceptional Computational Power: Robust FPGA/ARM processor architecture enables rapid, multi-dimensional optimization that keeps pace with complex dynamic changes

- Real-Time Model Updating: The system continuously updates its control model during testing to respond to non-linearities and time-varying dynamics, ensuring superior test accuracy and safety

- Predictive Control Technology: Forward-looking algorithms anticipate control errors before they occur, enabling faster response and more stable control under demanding test conditions

Detailed Feature Comparison: PANTHER vs Other Vibration Controllers

| Feature Category | PANTHER Vibration Controller | Other Vibration Controllers |

|---|---|---|

| User Interface & Ease of Use | Modern, intuitive GTX software interface designed for complete touch-screen operation on Windows 11 PCs and tablets, including Microsoft Surface. The advanced Library capability provides instant access to test setups and data files with intelligent aliasing and favorites for rapid recall. Streamlined workflows significantly reduce training time and test preparation. All applications operate within a unified environment, eliminating the need to learn multiple interfaces. | Most competitor interfaces are dated or overly complex, designed for mouse/keyboard only. Few offer genuine touch-screen support or integrated library systems for setup and data management. Multiple applications often require separate interfaces, increasing training requirements and operator errors. Manual navigation through file systems adds preparation time. |

| Safety & System Protection | PANTHER continuously monitors more than a dozen safety parameters up to 25 times per second. Intelligent abort logic and adaptive safeguards protect both test article and vibration equipment during every test. Safety functions are fully integrated into the control loop and operate continuously—not just during setup. Multi-level protection includes hardware watchdogs, software monitoring, and predictive abort algorithms that prevent damage before limits are exceeded. | Competitors typically rely on basic safety limits or manual abort switches. Their safety features are primarily reactive rather than predictive, offering less comprehensive protection for operators and test systems. Safety monitoring may be limited to simple threshold checking rather than intelligent analysis of multiple parameters. Update rates are typically slower, allowing potentially damaging conditions to persist longer. |

| Adaptive Control Algorithms | Employs patented, application-specific adaptive algorithms with advanced digital filters and optimization methods tailored for each test type. The control system continuously updates its internal model in real-time during testing, enabling optimal response to changing dynamics. Forward-looking predictive algorithms anticipate control errors before they occur. Specialized algorithms for sine, random, shock, SRS synthesis, and combined environmental testing ensure optimal performance for each application. | Utilize adaptive control schemes that are often more generalized rather than optimized for specific test types. Some systems focus on particular types of disturbances while being less effective with others. Algorithm sophistication varies widely among manufacturers, with some offering minimal adaptation beyond basic equalization. Proprietary algorithms rarely match the refinement of decades of Spectral Dynamics' research and development. |

| Computational Power & Architecture | State-of-the-art FPGA/multi-core ARM processor architecture delivers exceptional computational power for real-time multi-dimensional optimization across all input and control channels simultaneously. High-speed parallel processing enables complex calculations without compromising control loop speed. The FPGA offloads computationally intensive tasks from the ARM processor, achieving best-in-class performance-per-watt with a low carbon footprint. Handles up to 32 channels with 262,144 samples per second without degradation. | Lower-cost or less advanced systems may rely on general-purpose processors with limited computational resources, potentially leading to slower control response and compromised stability in complex scenarios. Processing bottlenecks can occur when multiple channels are active or during rapid transient events. Some systems must reduce sample rates or channel counts to maintain adequate control loop speed, limiting testing capabilities. |

| Control Speed & Stability | Provides exceptionally rapid equalization and maintains stable control even with highly non-linear system responses. Minimizes time to reach full test levels while protecting the test article and shaker equipment throughout. Advanced predictive algorithms enable stable control at the theoretical limits of closed-loop performance. Adaptive model updates occur seamlessly without disrupting test stability, even during rapid dynamic changes. | Control speed and stability vary significantly depending on the specific system and its computational capabilities. Less advanced systems may struggle to maintain stability with rapidly changing non-linearities or resonant conditions. Slower adaptation rates can result in extended equalization times and increased risk of over-testing or equipment damage. Some systems require manual intervention to maintain stability during challenging tests. |

| Test Type Optimization | Optimized adaptive control methods for the complete range of vibration testing applications: sine sweep, random vibration, classical shock, SRS shock synthesis, sine-on-random, random-on-random, and rotating machinery analysis. Each test type uses specialized algorithms rather than generic approaches. Gap-free data streaming is available in all applications, not just selected modes. Application-specific safety monitoring adapts to each test type's unique requirements. | Most modern controllers offer various test types, but the quality and sophistication of adaptive control varies significantly between modes. Some excel at certain test types while being mediocre at others. Combined environmental tests (like sine-on-random) may use less sophisticated control algorithms. Gap-free streaming and advanced features are often available only in premium modes or with additional licenses. |

| Non-Linearity Compensation | The adaptive algorithm and continuous real-time model updates enable PANTHER to rapidly and accurately compensate for complex non-linear structural behaviors including: resonance shifts, amplitude-dependent stiffness, friction non-linearities, and time-varying system dynamics. The controller recognizes and adapts to these challenging conditions automatically without manual intervention. Proprietary algorithms prevent common non-linear instabilities that plague less sophisticated systems. | Systems with less sophisticated algorithms are typically slower and less accurate when correcting non-linear responses, potentially requiring manual intervention or test modifications. Some controllers cannot distinguish between legitimate non-linear behavior and system instabilities, leading to unnecessary aborts or unsafe conditions. Adaptation to changing dynamics may be limited, forcing operators to restart tests or accept compromised control quality. |

| Data Acquisition & Analysis | Gap-free streaming to disk in ALL applications with simultaneous acquisition at up to 262,144 samples/second across all channels. Multiple independent data streams with different sample rates can be captured simultaneously—a unique PANTHER capability. TRUE 110+ dB dynamic range with 24-bit ADCs ensures accurate measurement of both large and small signals. Integrated analysis tools provide real-time insight without external software. All data is time-stamped and synchronized via single master clock. | Gap-free streaming may be limited to specific test types or unavailable entirely. Sample rates often must be reduced when multiple channels are active. Dynamic range specifications may be inflated marketing claims rather than achievable performance (130+ dB claims typically represent theoretical limits, not real-world capability). Separate software packages are often required for advanced analysis. Independent data streams are typically not supported. |

| System Scalability & Expansion | Scales from 8 to 32 fully phase-synchronized input channels in 8-channel increments. Multiple chassis can be synchronized using optional sync cables, maintaining phase matching better than ±0.10% across all channels and chassis. Software licenses expand with hardware, eliminating hidden upgrade costs. All PANTHER systems use identical software and architecture, ensuring consistent performance regardless of configuration. Field upgrades are straightforward and fully supported. | Channel expansion may require different hardware platforms or be limited by system architecture. Phase synchronization across multiple units is often less precise or requires expensive external synchronization hardware. Software capabilities may differ between system sizes, creating training challenges. Expansion often requires significant reconfiguration or system replacement rather than simple upgrades. Some manufacturers limit channel counts in their control systems. |